1480-1530°C (2696-2786°F)

- +91 22 66363099

- info@spmetal.net

What Is Stainless Steel Flange?

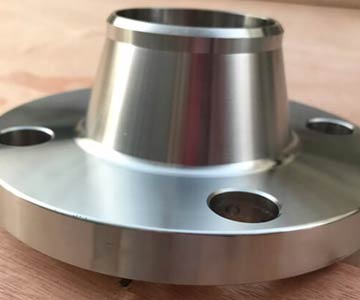

Stainless steel Flanges are components of ferrous groups, which are employed to connect pipes, valves, and other piping equipment. Stainless steel flanges have an 11% concentration of chromium, which helps in forming a protective layer. The layer inhibits corrosion and oxidation in different systems. The flanges in this range bolster superior strength and securely seal the entire system. These flanges can also be welded and maintained easily for long periods.

ASTM A182 Flanges Features

ASTM A182 flanges are forged martensitic stainless steel components. Some of the features of the A182 module includes:

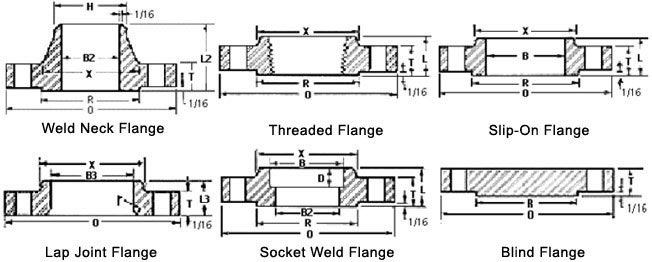

SS Blind Flanges Vs Stainless Steel Slip On Flange

Flanges are components, which are available in a range of sizes and shapes, and face types.

ASME SA 182 SS Weld Neck Flange Application

ASME SA 182 SS Weld Neck Flanges are some of the strongest flanges in the system. Their long protruding neck provides support to different components during rigorous movement and rising pressures across the system. They are generally seen in applications, where there are fluctuations in the temperatures and pressures. These flanges can be employed to handle volatile and hazardous fluids at sub-zero temperatures. Commonly seen in machinery industry, ring artifacts, welding dissimilar metal, oil and gas transportation, power generation, etc.

Difference Between Stainless Steel Threaded Flange And SS Lap Joint Flange

Table of Content

Stainless Steel Flange Material Specification

| Specifications | Stainless Steel Flanges |

|---|---|

| Grades |

|

| ASME B16.5 Stainless Steel Flanges size range | 1/2 inch (15 NB) to 48 inch (1200NB) DN10 to DN5000 |

| Stainless Steel Flanges Standards | B16.47 Series A & B, ANSI/ASME B16.5, B16.48, BS 10, BS4504, EN-1092, ANSI, DIN, ASME, DIN, BS, EN, GOST. |

| SS Flanges Standard ANSI | Class 150, 300, 600, 900, 1500, 2500 LBS |

| Stainless Steel Flanges Standard DIN | 6, 10, 16, 25, 40Bar /PN40 PN6 PN16 PN10 PN25 , PN64 |

| SS Flange Japan Standard JIS | 5, 10, 16, 20, 30, 40, 63 K |

| Stainless Steel Flanges Standard UNI | 6. 10. 16, 25, 40 Bar |

| European Standard Stainless Steel Flanges (EN) | 6, 10, 16, 25, 40 Bar |

| Main Types | Forged / Threaded / Screwed / Plate |

| Flange supporting material | Gasket, Ring Joint, Flange Bolts |

| Test Certificates provided by Stainless Steel Flanges manufacturers | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Most common types of Stainless Steel Flanges |

|

| Specialized manufacturer of |

|

| Production technique |

|

| Connect Type/ Flange Face Type | Flat Face (FF), Raised Face (RF), Ring Type Joint (RTJ), Large Male-Female (LMF), Small Male-Female (SMF), Lap-Joint Face (LJF), Small Tongue, Large Tongue & Groove Supplier in india |

| Special design | AS, BS, ANSI, DIN and JIS Stainless Steel Flanges Threaded Flanges, Socketweld Flanges, Slip-On Flanges, Blind Flanges, Weld Neck Flanges Supplier in India |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Bending machine, Press machine, electric bevelling machine, Pushing Machine, Sand-blasting machine etc |

| Origin | Indian / West Europe / Japan / USA / Korean |

| Specialized manufacturer of |

|

| Stainless Steel Flanges Standard | GOST, ANSI DIN, JIS, BS, UNI, AS2129, EN, SABS, AWWA, NFE etc.

|

| Key markets and industries for Stainless Steel Flanges |

|

| Stainless Steel Flanges Application |

|

| Material Test Certificates (MTC) as per 10204 3.2 and EN 10204 3.1 Test Certificates certifying NACE MR0175, NACE MR0103 | |

Stainless Steel Flanges

Stainless Steel Blind Flanges

Stainless Steel Slip On Flange

Stainless Steel Weld Neck Flange

Stainless Steel Forged Flange

Stainless Steel Pipe Flange

ASTM A182 Flanges

Stainless Steel Pipe Flange Melting

| Melting Point |

| 1402 °C (2555 °F) |

1480-1530°C (2696-2786°F)

Stainless Steel Blind Flanges Dimension

Dimensions: ANSI/ASME B16.5, B16.28, MSS-SP-43.

| Standard | Class | Diameter | Bolt Circle Diameter | Number of Bolts | Bolt Size | Diameter of Bolt Hole |

|---|---|---|---|---|---|---|

| AS4087 | PN14 | 95 | 67 | 4 | M12 | 14 |

| AS 2129 Flange | Table C | 95 | 67 | 4 | 13 | 14 |

| Table D | 95 | 67 | 4 | 13 | 14 | |

| Table E | 95 | 67 | 4 | 13 | 14 | |

| Table F | 95 | 67 | 4 | 13 | 14 | |

| Table H | 114 | 83 | 4 | 16 | 17 | |

| Table J | 114 | 83 | 4 | 16 | 17 | |

| ANSI B16.5 | ANSI 150 | 89 | 60 | 4 | 13 | 16 |

| ANSI 300 | 95 | 67 | 4 | 13 | 16 | |

| ANSI 600 | 95 | 67 | 4 | 13 | 16 | |

| ANSI 900 | 121 | 83 | 4 | 19 | 22 | |

| ANSI 1500 | 121 | 83 | 4 | 19 | 22 | |

| ISO 7005 (DIN) Flange | PN6 | 80 | 55 | 4 | M10 | 11 |

| PN10 | 95 | 65 | 4 | M12 | 14 | |

| PN16 | 95 | 65 | 4 | M12 | 14 | |

| PN20 | 90 | 60.5 | 4 | M14 | 16 | |

| PN25 | 95 | 65 | 4 | M12 | 14 | |

| PN40 | 95 | 65 | 4 | M12 | 14 |

Chemical Composition Of Stainless Steel Plate Flanges

| Type | C | Mn | P | S | Si | Cr | Ni | Mb |

|---|---|---|---|---|---|---|---|---|

| 302 | 0.15 | 2.00 | 0.045 | 0.030 | 1.00 | 17.00/19.00 | 8.00/10.00 | – |

| 304 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 18.00/20.00 | 8.00/10.50 | – |

| 304L | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 18.00/20.00 | 8.00/12.00 | – |

| 309 | 0.20 | 2.00 | 0.045 | 0.030 | 1.00 | 22.00/24.00 | 12.00/15.00 | – |

| 309S | 0.08 | 2.00 | 0.045 | – | 1.00 | 22.00/24.00 | – | – |

| 310 | 0.25 | 2.00 | 0.045 | 0.030 | 1.5 | 24.00/26.00 | 19.00/22.00 | – |

| 310S | 0.08 | 2.00 | 0.045 | 0.030 | 1.5 | 24.00/26.00 | 19.00/22.00 | – |

| 316 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 16.00/18.00 | 10.00/14.00 | 2.00/3.00 |

| 316L | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 16.00/18.00 | 10.00/14.00 | 2.00/3.00 |

| 317 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00/1.00 | 18.00/20.00 | 11.00/15.00 | 3.00/4.00 |

| 317L | 0.03 | 2.00 | 0.045 | 0.030 | 0.75 | 18.00/20.00 | 11.00/15.00 | 3.00/4.00 |

| 321 | 0.08 | 2.00 | 0.040 | 0.030 | 1.00 | 17.00/19.00 | 9.00/12.00 | 0.75/0.75 |

| 347 | 0.08 | 2.00 | 0.040 | 0.030 | 0.5/1.00 | 17.00/19.00 | 9.00/12.00 | 0.5/0.75 |

Ss Weld Neck Flange Grade

Stainless Steel Flange Price List

| SS Pipe Flange Price List | Piece | Per Unit (INR) | Price in (UAE Dirham) | Price in (Saudi Riyal) |

|---|---|---|---|---|

| ASME SA 182 SS Threaded Flange | 59 | 385 | 19.90 | 20.32 |

| Stainless Lap Joint Flange | 12 | 476 | 24.60 | 25.13 |

| Stainless Steel A 182 weld Neck Flange | 3 | 811 | 41.92 | 42.81 |

| Stainless Steel Blind Flange | 60 | 487 | 25.17 | 25.71 |

Mechanical Properties Of Stainless Steel Threaded Flanges

| Type | UNS | Tensile (ksi) min | Yield (ksi) min | Elongation min | Hardness (Brinell) max | Hardness (Rockwell B) max |

|---|---|---|---|---|---|---|

| 302 | S30200 | 75 | 30 | 40% in 2″ | 183 | 88 |

| 304 | S30400 | 75 | 30 | 40% in 2″ | 183 | 88 |

| 304L | S30403 | 70 | 30 | 40% in 2″ | 183 | 88 |

| 309 | S30900 | 75 | 30 | 40% in 2″ | 217 | 95 |

| 309S | S30908 | 75 | 30 | 40% in 2″ | 217 | 95 |

| 310 | S31000 | 75 | 30 | 40% in 2″ | 217 | 95 |

| 310S | S31008 | 75 | 30 | 40% in 2″ | 217 | 95 |

| 316 | S31600 | 75 | 30 | 40% in 2″ | 217 | 95 |

| 316L | S31603 | 70 | 25 | 35% in 2″ | 217 | 95 |

| 317 | S31700 | 75 | 30 | 35% in 2″ | 217 | 95 |

| 317L | S31703 | 75 | 30 | 35% in 2″ | 217 | 95 |

| 321 | S32100 | 75 | 30 | 40% in 2″ | 183 | 88 |

| 347 | S34700 | 75 | 30 | 40% in 2″ | 183 | 88 |

SS Plate Flanges Packaging

SS Flange Standard

| ASME B16.5 Stainless Steel Flanges | EN TYPE | DIN |

|---|---|---|

| WN – Welding Neck (WN) | EN-TYPE 11 | DIN 2631 DIN 2632 DIN 2633 DIN 2634 DIN 2635 |

| BL – Blind (BL) | EN-TYPE 05 | DIN 2527 |

| SO – Slip On (SO) | EN-TYPE 01/12 | |

| LJ – Lap Joint (LJ) | EN-TYPE 02/04 | DIN 2641 DIN 2642 DIN 2655 DIN 2656 |

| SW – Socket Weld (SW) | EN-TYPE 14 | |

| THR – Threaded (THR) | EN-TYPE 13 | DIN 2566 |

| LWN – Long Welding Neck / Integral(LWN) | EN-TYPE 21 | |

| Welding Collars | EN-TYPE 32/34 | |

| Welding for SS Flat Flanges | DIN 2573 DIN 2576 | |

| SS Lap Joint Short Stub End | DIN 2673 | |

| Chromium Nickel SS Orifice Flanges, Chromium Stainless Steel Swivel Flanges, Spacer Rings, Spades Ferritic Stainless Steel Spectable Blinds, VSM, NFE, API 6A, JIS B2220, BS10/BS4504, GOST | ||

| Stainless Steel Flanges Manufacturers In India | ||

| Stainless Steel Flanges | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. BS Flanges, EN Flanges, JIS/ KS Flanges, ANSI Flanges, ASME Flanges, DIN Flanges, API 6A Flanges, AWWA C207 Flanges, EN1092-1 Flanges, UNI Flanges,BS4504 Flanges, GB Flanges, GOST Flanges, PSI Flange

|

|---|

PED Certified Stainless Steel Flanges Manufacturer in India, Dimensions Of ASME B16.5 SS Blind Flanges In MM.

Size Range Of SS Forged Flanges

1/2” up to and including 24”

Forged Stainless Steel Flanges Equivalent

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| SS 304L | 1.4306 / 1.4307 | S30403 | SUS 304L | 3304S11 | 03Х18Н11 | Z3CN18‐10 | X2CrNi18-9 / X2CrNi19-11 |

| SS 304H | 1.4301 | S30409 | – | – | – | – | – |

| SS 310 | 1.4841 | S31000 | SUS 310 | 310S24 | 20Ch25N20S2 | – | X15CrNi25-20 |

| SS 310S | 1.4845 | S31008 | SUS 310S | 310S16 | 20Ch23N18 | – | X8CrNi25-21 |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

| SS 316Ti | 1.4571 | S31635 | SUS 316Ti | 320S31 | 08Ch17N13M2T | Z6CNDT17‐123 | X6CrNiMoTi17-12-2 |

| SS 317 | 1.4449 | S31700 | SUS 317 | – | – | – | – |

| SS 317L | 1.4438 | S31703 | SUS 317L | – | – | – | X2CrNiMo18-15-4 |

| SS 321 | 1.4541 | S32100 | SUS 321 | – | – | – | X6CrNiTi18-10 |

| SS 321H | 1.4878 | S32109 | SUS 321H | – | – | – | X12CrNiTi18-9 |

| SS 347 | 1.4550 | S34700 | SUS 347 | – | 08Ch18N12B | – | X6CrNiNb18-10 |

| SS 410 | 1.4006 | S41000 | SUS 410 | 410S21 | – | – | X12Cr13 |

| SS 446 | 1.4762 | S44600 | – | – | – | – | – |

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5 | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

Various Types Of Astm A182 Flanges

Stainless Steel Forged Flange Application

Class 150 Stainless Steel Flange Dimensions

| NPS | O.D. of Flange | Flanges Thickness | Diameter of RF | Diameter of Hub at Base | Lengtd Tdru Hub | Bore or Diameter | Dia. of Hub at Bevel | Radius of Fillet | Deptd of Socket | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Welding (WN) Neck | Slip-On (SORF) Threaded (NPT) Socket (SWRF) | Lap Joint (Loose) | Slip-on (SORF) Socket (SWRF) | Lap Joint (Loose) | ||||||||

| O | Q | R | X | Y | Y | Y | W | B | H | r | Z | |

| 1/2 | 3-1/2 | 7/16 | 1-3/8 | 1-3/16 | 1-7/8 | 5/8 | 5/8 | .88 | .90 | .84 | 1/8 | 3/8 |

| 3/4 | 3-7/8 | 1/2 | 1-11/16 | 1-1/2 | 2-1/16 | 5/8 | 5/8 | 1.09 | 1.11 | 1.05 | 1/8 | 7/16 |

| 1 | 4-1/4 | 9/16 | 2 | 1-15/16 | 2-3/16 | 11/16 | 11/16 | 1.36 | 1.38 | 1.32 | 1/8 | 1/2 |

| 1-1/4 | 4-5/8 | 5/8 | 2-1/2 | 2-5/16 | 2-1/4 | 13/16 | 13/16 | 1.70 | 1.72 | 1.66 | 3/16 | 9/16 |

| 1-1/2 | 5 | 11/16 | 2-7/8 | 2-9/16 | 2-7/16 | 7/8 | 7/8 | 1.95 | 1.97 | 1.90 | 1/4 | 5/8 |

| 2 | 6 | 3/4 | 3-5/8 | 3-1/16 | 2-1/2 | 1 | 1 | 2.44 | 2.46 | 2.38 | 5/16 | 11/16 |

| 2-1/2 | 7 | 7/8 | 4-1/8 | 3-9/16 | 2-3/4 | 1-1/8 | 1-1/8 | 2.94 | 2.97 | 2.88 | 5/16 | 3/4 |

| 3 | 7-1/2 | 15/16 | 5 | 4-1/4 | 2-3/4 | 1-3/16 | 1-3/16 | 3.57 | 3.60 | 3.50 | 3/8 | 13/16 |

| 3-1/2 | 8-1/2 | 15/16 | 5-1/2 | 4-13/16 | 2-13/16 | 1-1/4 | 1-1/4 | 4.07 | 4.10 | 4.00 | 3/8 | 7/8 |

| 4 | 9 | 15/16 | 6-3/16 | 5-5/16 | 3 | 1-5/16 | 1-5/16 | 4.57 | 4.60 | 4.50 | 7/16 | 15/16 |

| 5 | 10 | 15/16 | 7.5/16 | 6-7/16 | 3-1/2 | 1-7/16 | 1-7/16 | 5.66 | 5.69 | 5.56 | 7/16 | 15/16 |

| 6 | 11 | 1 | 8-1/2 | 7-9/16 | 3-1/2 | 1-9/16 | 1-9/16 | 6.72 | 6.75 | 6.63 | 1/2 | 1-1/16 |

| 8 | 13-1/2 | 1-1/8 | 10-5/8 | 9-11/16 | 4 | 1-3/4 | 1-3/4 | 8.72 | 8.75 | 8.63 | 1/2 | 1-1/4 |

| 10 | 16 | 1-3/16 | 12-3/4 | 12 | 4 | 1-15/16 | 1-15/16 | 10.88 | 10.92 | 10.75 | 1/2 | 1-5/16 |

| 12 | 19 | 1-1/4 | 15 | 14-3/8 | 4-1/2 | 2-3/16 | 2-3/16 | 12.88 | 12.92 | 12.75 | 1/2 | 1-9/16 |

| 14 | 21 | 1-3/8 | 16-1/4 | 15-3/4 | 5 | 2-1/4 | 3-1/8 | 14.14 | 14.18 | 14.00 | 1/2 | 1-5/8 |

| 16 | 23-1/2 | 1-7/16 | 18-1/2 | 18 | 5 | 2-1/2 | 3-7/16 | 16.16 | 16.19 | 16.00 | 1/2 | 1-3/4 |

| 18 | 25 | 1-9/16 | 21 | 19-7/8 | 5-1/2 | 2-11/16 | 3-13/16 | 18.18 | 18.20 | 18.00 | 1/2 | 1-15/16 |

| 20 | 27-1/2 | 1-11/16 | 23 | 22 | 5-11/16 | 2-7/8 | 4-1/16 | 20.20 | 20.25 | 20.00 | 1/2 | 2-1/8 |

| 24 | 32 | 1-7/8 | 27-1/4 | 26-1/8 | 6 | 3-1/4 | 4-3/8 | 24.25 | 24.25 | 24.00 | 1/2 | 2-1/2 |

SS Flange Hsn Code

| HS Code | Item Description | Policy |

|---|---|---|

| 73 | Iron or Steel | |

| 7307 | Tube Or Pipe Fittings (for Example, Couplings, Elbows, Sleeves), Of Iron Or Steel - Cast Fittings : | |

| 73072100 | Other, of stainless steel: Flanges | Free |

| Free | ||

Stainless Steel Puddle Flange Testing

Stainless Steel Socket Weld Flange Advantage