- +91 22 66363099

- info@spmetal.net

What is Alloy Steel Pipe?

Alloy Steel Pipe are components that are alloyed with a variety of elements between 1 to 50% by weight. These pipes can either be low or high alloy steel components. The higher the alloying material greater is the strength of the steel. The alloys make these modules extremely resistant to impact and stress. Apart from this, the overall corrosion resistance of the pipe is also affected by this process making, it a leading choice for different chemical companies.

Comparison Between ASTM A335 P11 Seamless Pipe and ASTM A335 P22 Pipe

ASTM A335 pipes exhibit higher percentages of alloying elements in comparison to standard pipes. P11 and P22 are the two major grades of pipes within this grade.

AISI 4140 tubes vs SAE AISI 4130 Chromoly Tube

41xx steels are high chromium and molybdenum-containing tubes, which possess superior strength compared to regular steel. Amongst these components are the AISI 4140 and SAE AISI 4130 Chromoly tubes. These tubes can be differentiated based on a range of aspects which are listed below.

ASME SA335 Grade 91 Pipe Welding Process

ASME SA335 Grade 91 pipes are utilized in critical applications, and any improper welds can result in a spectacular failure. This is why there are strict norms in welding products from this grade. The pipes from this grade can be welded using gas metal arc welding, gas tungsten arc welding, submerged arc welding, and flux-cored arc welding procedures. Welding is performed at temperatures between 400 to 550 degrees F. After the welding procedure takes place, the pipe is kept at elevated temperatures to dry. It is later heat-treated at 1900 degrees F and tempered or quenched.

ASTM A335 P5 Pipe Benefits

Some of the important benefits of the ASTM A335 P5 Pipe include

Alloy Steel Welded Pipe Uses

Alloy steel welded pipes are one of the most diverse pipes in the industry. These pipes are utilized in diverse markets such as petrochemicals, refineries, energy-related industries, and nuclear plants. These versatile components possess superior strength and performance due to their superior alloy concentration. This is why they are employed in solar plants, aerospace, atomic energy, defense, and so on.

Table of Content

Alloy Steel Tube Material Specification

| Specifications | ASTM A 335 ASME SA 335 |

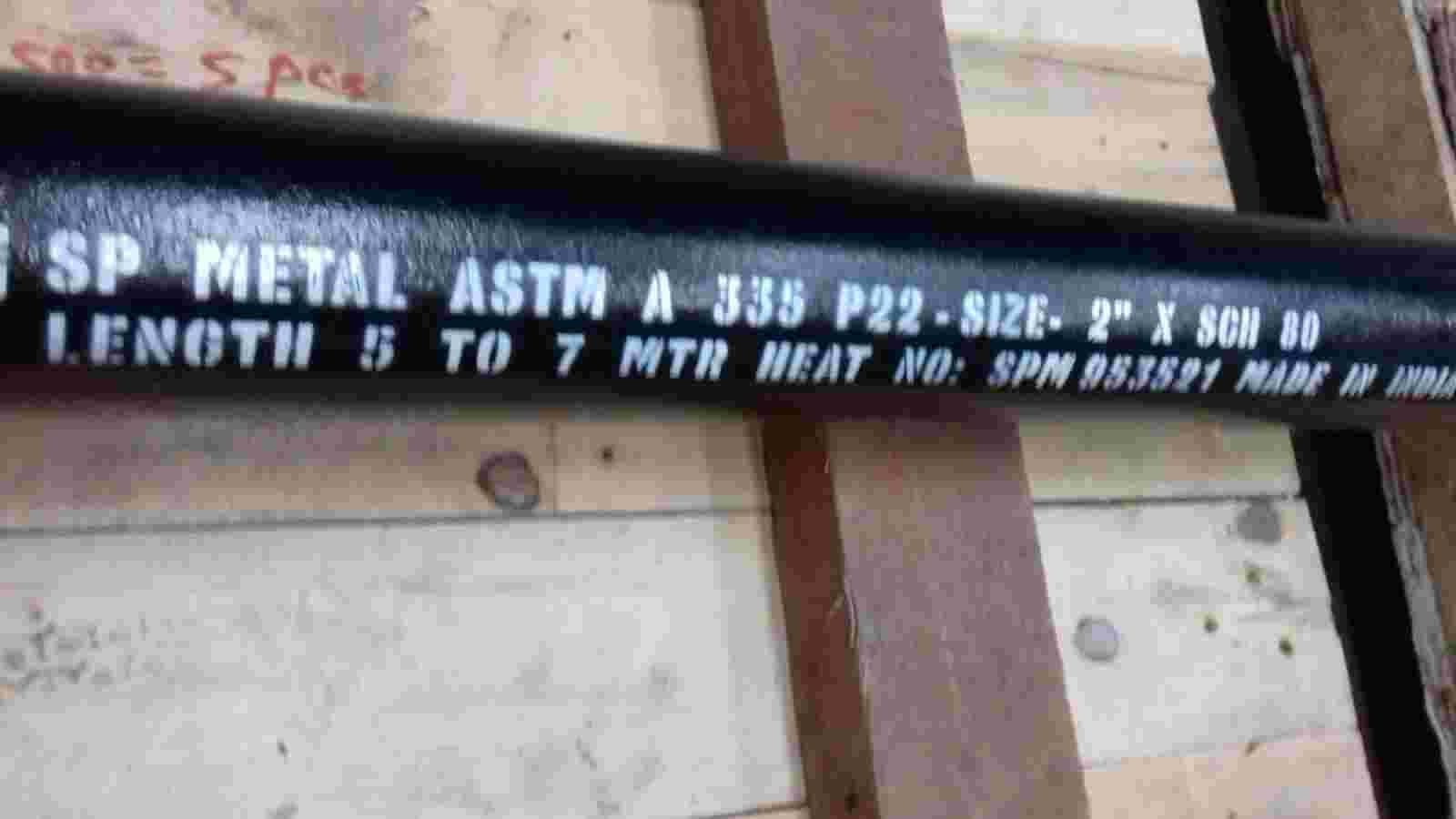

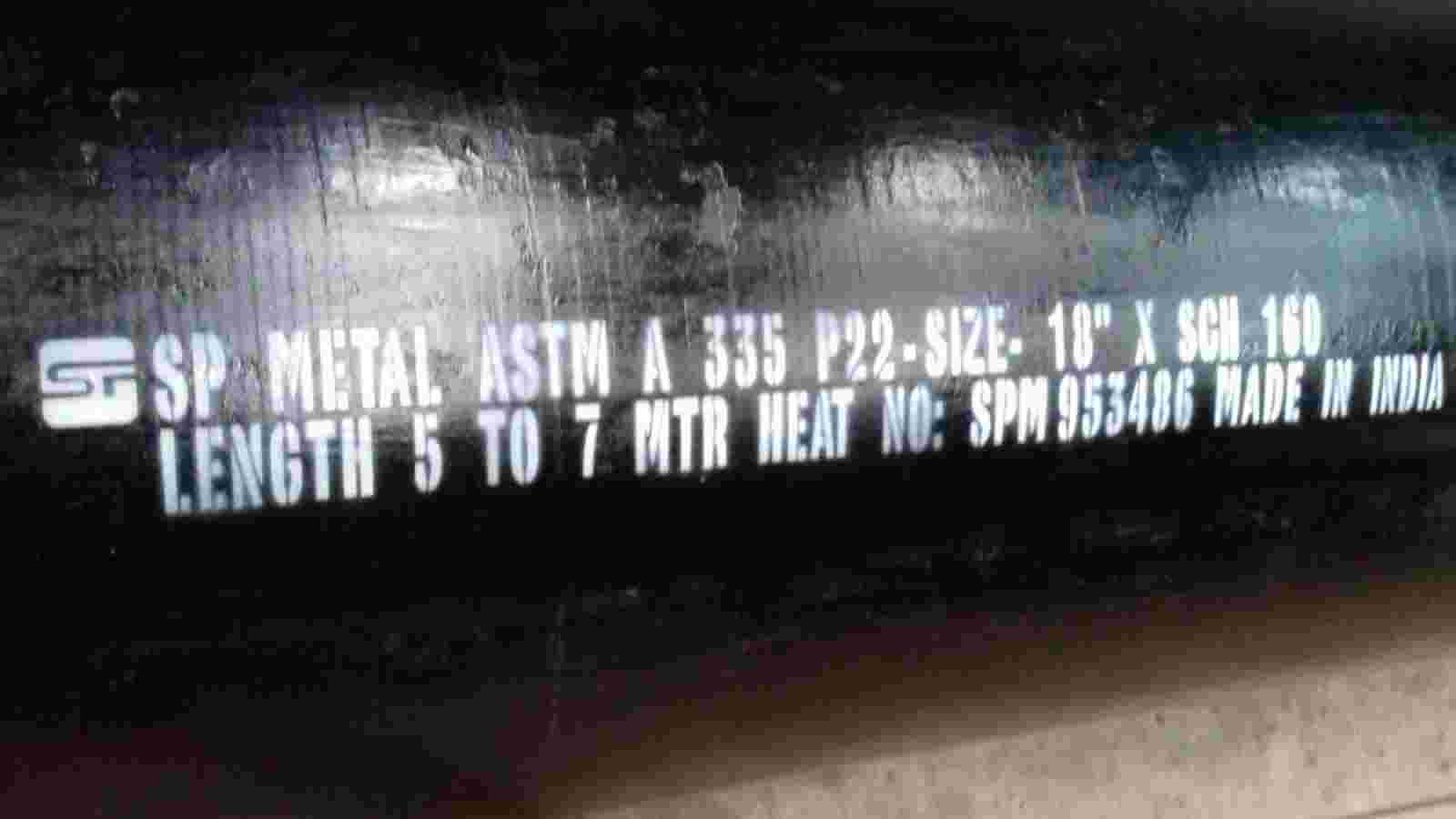

| Dimensions | ASTM, ASME and API |

| Pipe Marking | All Alloy steel pipe are marked as follows: Supplier or Manufacturer’s Name, Grade, Standard, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

|---|---|

| Size | 1/8″NB TO 30″NB IN |

| Tubing Size | 1 / 2” OD up to 5” OD, customs diameters also available |

| Outer Diameter | 6-2500mm; WT:1-200mm |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Grade | ASTM A335 Gr. P5, P9, P11, P12, P21, P22 & P91, ASTM A213 – T5, T9, T11, T12, T22, T91, ASTM A691 |

| Length | Within 13500mm |

| Test Certificate provided by supplier | EN 10204 3.1 B |

| Type | Seamless / Fabricated |

| Form | Round, Hydraulic Etc |

| Length | Single Random, Double Random & Cut Length. |

| End | Plain End, Beveled End, Treaded |

| Alloy Steel Pipe Suppliers In India | |

Alloy Steel Pipe

ASTM A335 P11 Pipe

Alloy Steel Tube

ASTM A335 P22 Pipe

Heat Treatment Of 4130 Alloy Steel Tube

| P5, P9, P11, and P22 | |||

| Grade | Heat Treatment Type | Normalizing Temperature Range F [C] | Subcritical Annealing or Tempering Temperature Range F [C] |

| P5 (b,c) | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| Subcritical Anneal (P5c only) | ***** | 1325 - 1375 [715 - 745] | |

| P9 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| P11 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1200 [650] | |

| P22 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| P91 | Normalize and Temper | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

| Quench and Temper | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

4140 Alloy Steel Tube Diameter

| ASTM A450 | Hot rolled | Outside Diameter, mm | Tolerance, mm |

| OD≤101.6 | +0.4/-0.8 | ||

| 101.6<OD≤190.5 | +0.4/-1.2 | ||

| 190.5<OD≤228.6 | +0.4/-1.6 | ||

| Cold Drawn | Outside Diameter, mm | Tolerance, mm | |

| OD<25.4 | ±0.10 | ||

| 25.4≤OD≤38.1 | ±0.15 | ||

| 38.1<OD<50.8 | ±0.20 | ||

| 50.8≤OD<63.5 | ±0.25 | ||

| 63.5≤OD<76.2 | ±0.30 | ||

| 76.2≤OD≤101.6 | ±0.38 | ||

| 101.6<OD≤190.5 | +0.38/-0.64 | ||

| 190.5<OD≤228.6 | +0.38/-1.14 | ||

| ASTM A530 & ASTM A335 | NPS | Outside Diameter, inch | Tolerance, mm |

| 1/8≤OD≤1-1/2 | ±0.40 | ||

| 1-1/2<OD≤4 | ±0.79 | ||

| 4<OD≤8 | +1.59/-0.79 | ||

| 8<OD≤12 | +2.38/-0.79 | ||

| OD>12 | ±1% |

Wall Thickness Of 4340 Alloy Steel Tube

| ASTM A450 | Hot rolled | Outside Diameter, mm | Tolerance, % |

| OD≤101.6, WT≤2.4 | +40/-0 | ||

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD≤101.6, WT>4.6 | +28/-0 | ||

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD>101.6, WT>4.6 | +28/-0 | ||

| Cold Drawn | Outside Diameter, mm | Tolerance, % | |

| OD≤38.1 | +20/-0 | ||

| OD>38.1 | +22/-0 | ||

| ASTM A530 | NPS | Outside Diameter, inch | Tolerance, % |

| 1/8≤OD≤2-1/2 | +20.0/-12.5 | ||

| 3≤OD≤18, WT/OD≤5% | +22.5/-12.5 | ||

| 3≤OD≤18, WT/OD>5% | +15.0/-12.5 | ||

| OD≥20, WT/OD≤5% | +22.5/-12.5 | ||

| OD≥20, WT/OD>5% | +15.0/-12.5 |

Alloy Steel Pipe Price Per Foot

| Description | length | outer Diameter | thickness | price in Us | price per foot in India |

| ASTM A335 Gr. P5 Alloy Steel Pipes | 6 meter | 1/2" NB to 36" NB | SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS | 4.07 | ₹304.87 |

| Alloy Steel Seamless Pipe, Size: 1/2 and 3 Inch | 18 meter | 1/2 inch, 1 inch, 2 inch, 3 inch, 4 inch, >4 | SCH 40, SCH 80, SCH 160 | 8.14 | ₹609.75 |

A335 Gr P11 Alloy Steel Pipe Grades

ASTM A335 P11 Pipe ASTM Code

| Material and types | Standard Code | Grades includes |

|---|---|---|

| Alloy Steel Seamless Ferritic and Austentic Boiler, Superheater, IBR approved Heat-Exchanger Tubes | ASTM A213/ ASME SA 213 | T1,T2,T5,T9,T11,T12,T22,T23,T91,T92 |

| High Temperature Alloy Steel Seamless Pipes (Ferritic) | ASTM A335/ ASME SA 335 | P1,P5,P9,P11,P12,P17,P22,P91,P92 |

| Carbon and Alloy Steel Seamless Mechanical Tubing | ASTM A519/ ASME SA 519 | 4130, 4130X,4140 |

| High Temperature Alloy Steel Seamless Pipes (Ferritic) | EN10216-2 | 13CrMo4-5 10CrMo9-10 X10CrMoVNb9-1 15NiCuMoNb5-6-4 |

SP Metals is biggest Alloy Steel Pipe Suppliers In India. Check Pressure rating of Alloy Steel Seamless Tube, Alloy Steel Erw Pipe

Pressure Rating Of Alloy Steel Square Tube

| NPS | OD | Sch | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (inches) | (inches) | 10 | 20 | STD | 30 | XS | 40 | 60 | 80 | 100 | XXS | 120 | 140 | 160 |

| 3/8 | 0.675 | 6606 | 9147 | 6606 | 9147 | |||||||||

| 1/2 | 0.84 | 6358 | 8575 | 6358 | 8575 | 17150 | 10908 | |||||||

| 1 | 1.315 | 4956 | 6670 | 4956 | 6670 | 13340 | 9316 | |||||||

| 1 1/4 | 1.66 | 4133 | 5638 | 4133 | 5638 | 11276 | 7380 | |||||||

| 2 | 2.375 | 3177 | 4498 | 3177 | 4498 | 8995 | 7097 | |||||||

| 2 1/2 | 2.875 | 3460 | 4704 | 3460 | 4704 | 9408 | 6391 | |||||||

| 3 1/2 | 4 | 2769 | 3896 | 2769 | 3896 | |||||||||

| 4 | 4.5 | 2581 | 3670 | 2581 | 3670 | 7339 | 4769 | 5782 | ||||||

| 6 | 6.625 | 2071 | 3195 | 2071 | 3195 | 6390 | 4157 | 5318 | ||||||

| 8 | 8.625 | 1420 | 1829 | 1574 | 2841 | 1829 | 2307 | 2841 | 3375 | 4971 | 4085 | 4613 | 5147 | |

| 12 | 12.75 | 961 | 1441 | 1268 | 1922 | 1560 | 2160 | 2644 | 3244 | 3843 | 3843 | 4324 | 5042 | |

| 14 | 14 | 875 | 1092 | 1313 | 1313 | 1750 | 1533 | 2079 | 2625 | 3283 | 3829 | 4375 | 4921 | |

| 18 | 18 | 681 | 849 | 1021 | 1192 | 1361 | 1530 | 2042 | 2553 | 3147 | 3743 | 4252 | 4848 | |

| 20 | 20 | 613 | 919 | 919 | 1225 | 1225 | 1455 | 1989 | 2526 | 3138 | 3675 | 4288 | 4824 | |

| 24 | 24 | 510 | 766 | 766 | 1147 | 1021 | 1405 | 1978 | 2489 | 3126 | 3700 | 4210 | 4786 | |

| 30 | 30 | 510 | 817 | 613 | 1021 | 817 | ||||||||

| 34 | 34 | 450 | 721 | 540 | 901 | 992 | ||||||||

| 42 | 42 | 583 | 438 | 729 | 875 | |||||||||

Alloy Steel Welded Pipe Vs Alloy Steel Erw Pipe Price

| Description | price in Us | price per kg in India |

| 20Cr 30Cr 35Cr alloy steel welded pipe | US $0.625-$1.25 | ₹ 46.83 - 93.66 |

| aisi 4130 alloy steel erw pipe | US $0.60-$1.00 | ₹ 44.96 - 74.93 |

| Alloy Steel welded Tubes, Size: 3 inch | US 2.34 | ₹ 175 |

| Alloy Steel ERW Pipe ASME A 335 GR P23 | US 2.00 | ₹ 150 |

| Welded A335 P1 Pipe | US 3.34 | ₹ 250 |

4130 Alloy Steel Tube Suppliers in India, We provide 4140 Alloy Steel Tube with instant delivery, 4340 Alloy Steel Tube weight Chart.

Seamless Alloy Steel Tube Supplier In India, Visit our 2mm diameter mirror polished Alloy Steel Square Tube in India, Call Now to Get Alloy Steel Boiler Tubes Free sample.

Types Of Alloy Steel Boiler Tubes

ASME Sa213 T11 Low Alloy Steel Tube En Standards

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Seamless Ferritic Alloy Steel Pipes for High Temperature Use | EN10216-2 | Ø8"~42" x WT15~100 | 13CrMo4-5, 1-CrMo9-10, X10CrMoVNb9-1, 15NiCuMoNb5-6-4 |

Alloy Steel Seamless Pipe Length

| Alloy Steel Pipe Types | Out diameter | Wall thickness | Length |

|---|---|---|---|

| NB Sizes (in stock) | 1/8” ~ 8” | SCH 5 / SCH 10 / SCH 40 / SCH 80 / SCH 160 | Upto 6 Meters |

| Alloy Steel Seamless Pipe (Custom Sizes) | 5.0mm ~ 203.2mm | As per requirement | Upto 6 Meters |

| Alloy Steel Welded Pipe (in Stock + Custom Sizes) | 5.0mm ~ 1219.2mm | 1.0 ~ 15.0 mm | Upto 6 Meters |

Equivalent Of ASTM A335 P5 Seamless Pipe

| Name | Temper | Specification |

|---|---|---|

| Alloy4130 | N | MILT6736, AMS6360, AMS6371 |

| Alloy4140 | N,A, T | AMS6381 |

| Alloy15CDV6 | T1080, T980 | AIR9160C, 1.7734.5, 1.7734.6 |

ISO Certified Alloy Steel Pipe Supplier in Mumbai, India, Tolerance Of Alloy Steel Tube Material In MM.

ASTM A335 P5 Pipe Diameter Tolernce

| A335 Pipes | Over | Under | ||

| NPS [DN] | in. | mm | in. | mm |

| 1/8 to 1 1/2 / DN 6 to 40 | 1/64 (0.015) | 0.4 | 1/64 (0.015) | 0.4 |

| Over 1 1/2 to 4 / DN 40 to 100 | 1/32 (0.031) | 0.79 | 1/32 (0.031) | 0.79 |

| Over 4 to 8 / DN 100 to 200 | 1/16 (0.062) | 1.59 | 1/32 (0.031) | 0.79 |

| Over 8 to 12 / DN 200 to 300 | 3/32 (0.093) | 2.38 | 1/32 (0.031) | 0.79 |

| Over 12 / > DN 300 | +/- 1% of the specified outside diameter | |||

ASTM A335 P1 Pipe Elogation

| Calculated Minimum Elongation Values | |||||

| Elongation in 2 in. or 50 mm, min % | |||||

| Wall Thickness | P5, P9, P11, P22 | P91 (type 1 and 2) | |||

| in. | mm | Longitudinal | Transverse | Longitudinal | |

| 5/16 (0.312) | 8 | 30 | 20 | 20 | |

| 9/32 (0.281) | 7.2 | 28 | 19 | 19 | |

| 1/4 (0.250) | 6.4 | 27 | 18 | 18 | |

| 7/32 (0.219) | 5.6 | 26 | 17 | ||

| 3/16 (0.188) | 4.8 | 24 | 16 | ||

| 5/32 (0.156) | 4 | 22 | 15 | ||

| 7/8 (0.125) | 3.2 | 21 | 14 | ||

| 3/32 (0.094) | 2.4 | 20 | 13 | ||

| 1/18 (0.062) | 1.6 | 18 | 12 | ||

ASTM A335 P11 Alloy Steel Pipe Tensile Strength

| P5 | P9 | P11 | P22 | P91 (1, 2) | P91 type 1 and 2 shall have a hardness within the range of 190 to 250 [HBW] or 196 to 265 [HV] or 91 HRBW to 25 HRC. | |||

| Tensile Strength, min., psi | ||||||||

| ksi | 60 | 60 | 60 | 60 | 85 | |||

| MPa | 415 | 415 | 415 | 415 | 585 | |||

| Yield Strength, min., psi | ||||||||

| ksi | 30 | 30 | 30 | 30 | 60 | |||

| MPa | 205 | 205 | 205 | 205 | 415 | |||

ASTM A335 P22 Pipe Packaging

Chemical Behaviour Of ASTM A335 P91 Pipe

| ASTM A335 Low-Alloy Steel (Grades) | UNS equivalent | C≤ | Mn | P≤ | S≤ | Si≤ | Cr | Mo |

| P1 | K11522 | 0.10~0.20 | 0.30~0.80 | 0.025 | 0.025 | 0.10~0.50 | – | 0.44~0.65 |

| P2 | K11547 | 0.10~0.20 | 0.30~0.61 | 0.025 | 0.025 | 0.10~0.30 | 0.50~0.81 | 0.44~0.65 |

| P5 | K41545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 4.00~6.00 | 0.44~0.65 |

| P5b | K51545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.00~2.00 | 4.00~6.00 | 0.44~0.65 |

| P5c | K41245 | 0.12 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 4.00~6.00 | 0.44~0.65 |

| P9 | S50400 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50~1.00 | 8.00~10.00 | 0.44~0.65 |

| P11 | K11597 | 0.05~0.15 | 0.30~0.61 | 0.025 | 0.025 | 0.50~1.00 | 1.00~1.50 | 0.44~0.65 |

| P12 | K11562 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 0.80~1.25 | 0.44~0.65 |

| P15 | K11578 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.15~1.65 | – | 0.44~0.65 |

| P21 | K31545 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 2.65~3.35 | 0.80~1.60 |

| P22 | K21590 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 1.90~2.60 | 0.87~1.13 |

| P91 | K91560 | 0.08~0.12 | 0.30~0.60 | 0.02 | 0.01 | 0.20~0.50 | 8.00~9.50 | 0.85~1.05 |

| P92 | K92460 | 0.07~0.13 | 0.30~0.60 | 0.02 | 0.01 | 0.5 | 8.50~9.50 | 0.30~0.60 |

ASME Sa213 T11 Low Alloy Steel Tube Suppliers In Mumbai, India, Get Free Quote For Alloy Steel Seamless Pipe, Mechanical Properties Of ASTM A335 P5 Seamless Pipe

Alloy Steel Seamless Tube Mechanical Properties

| A335 Low-Alloy Pipe | UNS Number | Yield Strength ksi | Tensile Strength ksi | Elongation % | Rockwell | Brinell |

| P1 | K11522 | 30 | 55 | 30 | – | – |

| P2 | K11547 | 30 | 55 | 30 | – | – |

| P5 | K41545 | 40 | 70 | 30 | – | 207 max |

| P9 | S50400 | 30 | 60 | 30 | – | – |

| P11 | K11597 | 30 | 60 | 20 | – | – |

| P12 | K11562 | 32 | 60 | 30 | – | 174 max |

| P22 | K21590 | 30 | 60 | 30 | – | – |

| P91 | K91560 | 60 | 85 | 20 | – | – |

ALLOY PIPE CROSS REFERENCE TABLE ASTM vs. EN GRADES

| Chrome Moly Pipes: Werkstoff vs EN vs ASTM | ||

|---|---|---|

| Werkstoff /DIN | EN | ASTM |

| 1.5415 | 16Mo3 | A335 Grade P1 |

| 1.7335 | 13CrMo4-5 | A335 Grade P11, P12 |

| 1.7380 | 10CrMo9-10 | A335 Grade P22 |

| 1.7362 | X11CrMo5 | A335 Grade P5 |

| A335 Grade P9 | ||

| 1.4903 | X10CrMoVNb9-1 | A335 Grade P91 |

Seamless Alloy Steel Pipes And Tubes Advantage

Alloy Steel Pipe Hs Code

| HSN Code | Product Description |

|---|---|

| 7306 | Other tubes, pipes and hollow profiles (for example, open seam or welded, riveted or similarly closed), of iron or steel |

| 730630 | Other welded of circular cross- section of iron or non-alloy steel: |

| 73063090 | Other |

| 7307 | Tube or pipe fittings (for example, couplings, elbows, sleeves), of iron or steel |

| 730793 | Butt welding fittings: |

| 73079390 | Other |

| 73072900 | Other |

Uses Of SAE Aisi 4130 Chromoly Tube

Thermal Properties Of ASME Sa335 Grade 91 Pipe

| Properties | Metric | Imperial |

|---|---|---|

| Thermal expansion coefficient (@ 0-100°C/32-212°F) | 12.2 µm/m°C | 6.78 µin/in°F |

| Thermal conductivity (@ 100°C) | 42.6 W/mK | 296 BTU in/hr.ft².°F |

Other Designations Of Aisi 4140 Tubes

| AMS 6349 | ASTM A193 (B7, B7M) | ASTM A506 (4140) | ASTM A752 (4140) |

| AMS 6381 | ASTM A194 (7, 7M) | ASTM A513 | ASTM A829 |

| AMS 6382 | ASTM A29 (4140) | ASTM A513 (4140) | SAE J1397 (4140) |

| AMS 6390 | ASTM A320 (L7, L7M, L7D) | ASTM A519 (4140) | SAE J404 (4140) |

| AMS 6395 | ASTM A322 (4140) | ASTM A646 (4140) | SAE J412 (4140) |

| AMS 6529 | ASTM A331 (4140) | ASTM A711 |

Alloy Steel Welded Pipe Forging

AISI 4140 alloy steel is forged at 926 to 1205°C (1700 to 2200°F)

Alloy Steel Erw Pipe Hotworking Properties

AISI 4140 alloy steel can be hot worked at 816 to 1038°C (1500 to 1900°F)

Trade Name Of 4130 Seamless Alloy Steel Tubing

| Trade Name | Grade | UNS # | Heater Tubes |

| 1 1/4 Chrome | T11 | K11597 | A213 |

| 2 1/4 Chrome | T22 | K21590 | A213 |

| 5 Chrome | T5 | K41545 | A213 |

| 9 Chrome | T9 | K90941 | A213 |

| T91 | T91 | K90901 | A213 |

| T92 | T92 | K92460 | A213 |