UNS S32760 Super Duplex 2507 Plate Density : 0.28 lb/in3

- +91 22 66363099

- info@spmetal.net

What is Super Duplex Plate?

Super Duplex Plate are composed of high alloy duplex steel material that is designed with a dual microstructure of ferritic and austenitic grades. The mixture of both these grades gives these plates excellent resistance against corrosion, stress cracking, and oxidation. The plates in this grade are employed in building structures that require high strength and durability. Designed with sizes above 6mm, these plates show excellent resistance against pitting by chlorides, making them well suited for marine applications

2507 Sheet Oil and Gas Application

A 2507 Sheet metal is a dual structure ferritic and austenitic grade, which possesses excellent resistance to corrosion and oxidation systems. These sheets are employed in weight-saving across oil and gas systems. The rigid structures can withstand a range of temperatures while being resistant to cracking due to acids. In the oil and systems, they can be seen in refining equipment, cooling tanks, processing systems, heat exchanger equipment, and so on.

Comparision Between UNS S32750 Foils and UNS S32550 Plate

UNS S32750 Foil and UNS S32550 Plate can be easily distinguished based on their gauge thickness.

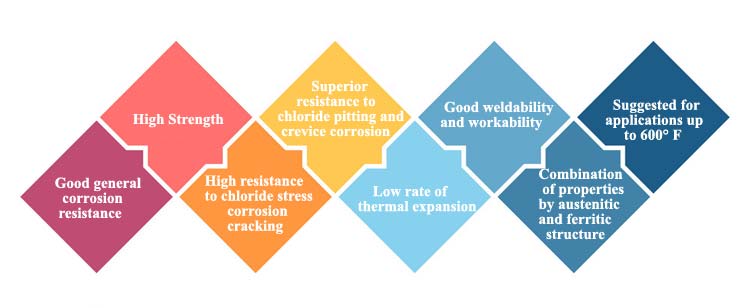

ASTM A240 Grade 2507 Material Features

Some of the features of the ASTM A240 Grade 2507 material include:

SDSS Coil VS Super Duplex 2507 Shim Sheet

SDSS coil and Super Duplex 2507 shim sheet are amongst the two versatile components within this grade. Both these modules can be differentiated based on certain features.

Difference Between SAF 2507 Sheets and en 1.4410 Plate

Sheets and metals can be classified based on their thickness and functions.

Table of Content

Super Duplex Plate Specification

| Specifications | ASTM A240 / ASME SA240 |

| Thickness | 4mm-100mm |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

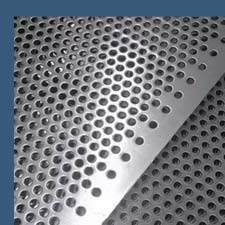

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

Super Duplex Plate

Super Duplex Sheet

Alloy 2507 Shim Sheet

2507 Duplex Stainless Steel Plate Price

| Description | Price in US | Price in India |

| super duplex 2507 stainless steel plate | US $3.00-$35.00 / Kilogram | 222.77 - 2599.01 |

| 2507 super duplex stainless steel plate thick plate thin plate | US $1.30-$2.00 / Kilogram | 96.53 - 148.51 |

| UNS S32750 ASTM-A240 NO.1 Super Duplex Stainless Steel Plate | US $4.00-$4.50 / Kilogram | 297.03 - 334.16 |

| 2507 stainless steel plate | US $1.00-$3.00 / Kilogram | 74.26 - 222.77 |

UNS S32750 Strip Density

UNS S32760 Super Duplex 2507 Plate Density : 0.28 lb/in3

Super Duplex 2507 Sheet Melting Point

| ASTM A240 Type 2507 Super Duplex Plate melting range |

| 2570 - 2660 °F (1410 - 1460 °C) |

UNS S32550 Foils Distributors

Get instant delivery Of 2 Inch Super Duplex Plate, Super Duplex Sheet Suppliers In Mumbai, India.

S32550 Plate Uses

ASTM A240 Grade 2507 Material Chemical Composition

| C | Cr | Ni | Mo | N | Others |

|---|---|---|---|---|---|

| 0.020 | 25 | 7 | 4.0 | .27 | S=0.001 |

Prestige quality Super Duplex Plate Supplier in India offer in EN, DIN, ISO, BS, JIS or ANSI standard.

Duplex 2507 Plate Features

Super Duplex Stainless Steel Plates Size

| Available Sizes | |

|---|---|

| Size (in millimeter) | Size (in inches) |

| 3.40 millimeter | .134" |

| 3.18 millimeter | .125" |

| 4.75 millimeter | .187" |

| 3.96 millimeter | .156" |

| 7.92 millimeter | .312" |

| 6.35 millimeter | .250" |

| 12.7 millimeter | .500" |

| 9.53 millimeter | .375" |

| 19.1 millimeter | .750" |

| 15.9 millimeter | .600" |

| 25.4 millimeter | 1" |

| 22.2 millimeter | .875" |

| 31.8 millimeter | 1.250" |

| 28.6 millimeter | 1.125" |

| 44.5 millimeter | 1.750" |

| 38.1 millimeter | 1.500" |

| 63.5 millimeter | 2.500" |

| 50.8 millimeter | 2" |

| 76.2 millimeter | 3" |

SP Metals is an ISO certified UNS S32750 Foils Supplier in India & S32550 Plate distributor in Mumbai

Difference Between Super Duplex 2507 Sheet, Plate & Foil

UNS S32750 Plate Physical Composition

| Density | lb/in3 | 0.28 |

|---|---|---|

| Modulus of Elasticity | psi x 106 | 29 |

| Coefficient of Thermal Expansion 68-212°F/°F | x10-6/°F | 7.2 |

| Thermal Conductivity | Btu/h ft °F | 8.7 |

| Heat Capacity | Btu/lb/°F | 0.12 |

| Electrical Resistivity | W-in x 10-6 | 31.5 |

ISO Approved en 1.4410 Plate Supplier In India. Also Check ASTM A240 Grade 2507 Shim Sheet Mechanical Properties

UNS S32760 Super Duplex Coil Mechanical Properties

| Ultimate Tensile Strength, ksi | 116 min. |

|---|---|

| 0.2% Offset Yield Strength 0.2%, ksi | 80 min. |

| 0.1% Offset Yield Strength 0.2%, ksi | 91 min. |

| Elongation in 2 inches, % | 15 min. |

| Hardness Rockwell C | 32 max. |

| Impact Energy, ft.-lbs. | 74 min. |

Types Of Super Duplex Sheet

Super Duplex Stainless Steel Plate Stock

| 2507 Duplex Stainless Steel Sheet | super duplex 2507 hot rolled plate |

| 2B HL No.4 mirror super duplex stainless steel sheet | Super duplex 2507 Sheet with BA surface |

| Super Duplex 2507 UNS S32750 Cold Rollled Plate | Super Duplex 2507 Sheet |

| ASME SA240 Super Duplex Steel S32750 Strip Tape | Hairline BA Mirror Finish 0.8mm Thick 2507 Super Duplex Plate |

| Duplex 2507 Stainless Steel Cold Rolled Plate | 2B Surface 2507 Super Duplex BBQ Plate |

| 2507 Stainless Steel Sheet for Oil and gas industry | cold rolled s32750 super duplex sheet |

| 2507 super duplex Checker Plate | NO 1 2B S32750 super duplex plate |

| ASTM A240 Cold rolled Duplex steel 2507 Coil | 1.4410 Super Duplex 2507 Hot Rolled Plate |

| 2507 Stainless Steel Sheet | S32750 SAF 2507 stainless steel plate |

| Super Duplex 2507 3mm Thick Coil | Super Duplex Stainless Steel Sheet |

Super Duplex Plates Manufacturers in India, Suppliers Of UNS S32750 Plate In Mumbai, One Stop Shop For All SDSS Coil.

2507 Shim Sheet Temperature Range

| Temperature °F | RT | 32 | -4 | -40 |

|---|---|---|---|---|

| Ft-lbs | 162 | 162 | 155 | 140 |

| Temperature °F | -76 | -112 | -148 | -320 |

| Ft-lbs | 110 | 44 | 30 | 7 |

Tensile Strength Of Super Duplex 2507 Plate

| Temperature °F | 68 | 212 | 302 | 392 | 482 |

|---|---|---|---|---|---|

| 0.2% Offset Yield Strength, ksi | 80 | 65 | 61 | 58 | 55 |

| Ultimate Tensile Strength, ksi | 116 | 101 | 98 | 95 | 94 |

En 1.4410 Plate Toughness

| Temp. | -50°C | +20°C | -60°F | +70°F |

|---|---|---|---|---|

| Single | 75 J/cm_ | 90 J/cm_ | 54 ft. lbs | 65 ft. lbs |

| Average (5) | 90 J/cm_ | 150 J/cm | 65 ft. lbs | 87 ft. lbs |

SP Metals is an ISO certified Super Duplex Shim Sheet Suppliers in India & Super Duplex 2507 Plate Stockist in Mumbai.

Saf 2507 Sheets Hardness

| Average (5) | HV10 180-230 | HB : 180-230 | HRC _ 20 |

Duplex S32550 Plate Hot Cold Forming

Hot forming of 2507 Super Duplex Plate

2507 should be hot worked between 1875°F and 2250°F. This should be followed by a solution anneal at 1925°F minimum and a rapid air or water quench.

Cold Forming Duplex 2507 Plate

Most of the common stainless steel forming methods can be used for cold working 2507.

Super Duplex Sheets Equivalent

| STANDARD | WERKSTOFF NR. | UNS |

| Super Duplex 2507 Plate / Sheet | 1.4410 | S32750/ S32760 |

Super Duplex Plate Dimensions In Mm

ASTM A240 Type 2507 Super Duplex Sheet Dimensions Imperial

| Surface finish of Plate | (max in) Width | (in)Gauge |

|---|---|---|

| 2D – heat treated, Cold rolled, pickled plate | 60 | 12–24 |

| Temper rolled plate Mexinox only | 48 | 13–29 |

| 2B – heat treated, Cold rolled, pickled, skin passed Plate | 72* | 10–24 |

| (not brushed) Polished plate | 60 | 11–24 |

| BA Mexinox only | 48 | 18–28 |

SA 240 GR 2507 Super Duplex Sheet Dimensions in Metric

| Surface finish of Plate | (mm) Thickness | (maximum mm) Width |

|---|---|---|

| 2D to heat treated, Cold rolled, pickled plate | 0.4 to 6.35 | 1524 |

| 2H to Work hardened plate | 0.4 to 6.35 | 1524 |

| 2B to heat treated, Cold rolled, pickled, skin passed plate | 0.25 to 8.0 | 2032 |

| brushed, Polished plate | 0.5 to 4.0 | 1524 |

| 2R to bright annealed, Cold rolled plate | 0.25 to 3.5 | 1524 |

| 2E to heat treated, Cold rolled, mechanically descaled plate | 0.4 to 8.0 | 2032 |

Welding Proces Of Sa 240 Gr 2507 Plate

| Material | Grade | Composition of Base Metal | SAW / GMAW /GTAW Tigrod/Autrod | UNS | FCAW |

|---|---|---|---|---|---|

| Super Duplex 2507 Plate | Zeron 100 | 6Ni, 25Cr, , 0.7Cu, 3Mo 0.25N, 0.7W | ER2509 | S32760 | SB 2509 |

| Ferralium 255 UR52N+ | 3Mo, 6Ni, 0.20N, 2Cu, 25Cr | S32550 | |||

| (SAF) 2507 | 7Ni, 25Cr, 0.25N, 4Mo | S32750 | |||

| UR47N | 6.5Ni, 25Cr, 0.18N, 3Mo | S31200 |

UNS S32760 Super Duplex Sheet Packaging

Super Duplex 2507 Sheet Hscode

| HS Code | Description |

|---|---|

| 72193590 | C.R. SECOND CHOICE S.S. SHEET/PLATE DUPLEX 2507 (SIZE: THK:3TO 6 MM X WIDTH: 1500 TO 2000 MM X LENGTH: 2560 TO 3000 MM) |

| 72193390 | STAINLESS STEEL DEFECTIVE SHEETS / PLATES DUPLEX GRADE 2507 [SWEDEN ORIGIN] |

| 72191190 | HOT ROLLED DEFECTIVE STAINLESS STEEL SHEETS / PLATES DUPLEX2507 |

| 72192490 | STAINLESS STEEL HOT ROLLED DEFECTIVE PLATE DUPLEX GRADE 2507 |

Super Duplex Plate Weight

| Weight of Plate | Thickness inch inchches |

|---|---|

| 00.08 lbs/inch²56.245568 kilogram/m² | 1/4 |

| 00.06000 lbs/inch²42.184176 kilogram/m² | 3/16 |

| 00.161 lbs/inch²113.1942056 kilogram/m² | 1/2 |

| 00.121 lbs/inch²85.0714216 kilogram/m² | 3/8 |

| 00.391 lbs/inch²274.9002136 kilogram/m² | 1 1/4 |

| 00.235 lbs/inch²165.221356 kilogram/m² | 3/4 |

| 00.196 lbs/inch²137.8016416 kilogram/m² | 5/8 |

| 00.313 lbs/inch²2200.0607848 kilogram/m² | 1 |

| 00.627 lbs/inch²4400.8246392 kilogram/m² | 2 |

| 00.941 lbs/inch²661.5884936 kilogram/m² | 3 |

| 00.274 lbs/inch²192.6410704 kilogram/m² | 7/8 |

| 00.862 lbs/inch²606.0459952 kilogram/m² | 2 3/4 |

| 00.549 lbs/inch²385.9852104 kilogram/m² | 1 3/4 |

| 00.47 lbs/inch²3300.442712 kilogram/m² | 1 1/2 |

| 00.784 lbs/inch²551.2065664 kilogram/m² | 2 1/2 |

| 00.705 lbs/inch²495.664068 kilogram/m² | 2 1/4 |

Super Duplex 2507 Plate For Sale

| Super Duplex 2507 Alloy Sheet | Super Duplex 2507 Werkstoff 1.4410 Sheet |

| Super Duplex 2507 Stainless Steel Strips | 2507 Super Duplex 1.4410 Flat |

| Super Duplex SS 2507 Coil | Super Duplex 2507 Grade F51 Sheet |

| Super Duplex 2507 Sheet | Inox Super Duplex 2507 Coil |

| Super Duplex 2507 Steel Flat | Super Duplex Type 2507 Plate |

| Avesta 2507 Plate | Lean Super Duplex 2507 Flat |

| 2507 Super Duplex Stainless Steel Coil | 25cr Super Duplex Stainless Steel Plate |

| 2507 Super Duplex Flat | Super Duplex 2507 F60 Plate |

| SA 240 GR 2507 Plate | 25cr Super Duplex Stainless Flat |

| 2507 Super Duplex SS Sheet | 25cr Super Duplex Steel Sheet |

| 2507 Super Duplex Stainless Steel Plate | 1.4410 Saf 2507 Sheet |

| 2507 Super Duplex Steel Sheet | 1.4410 Super Duplex 2507 Coil |

| 25cr Super Duplex Sheet | Super Duplex 2507 Grade Sheet |

| Super Duplex 2507 AISI Plate | Super Duplex Stainless Steel Grade 2507 Coil |

| 25 Cr Super Duplex Coil | Super Duplex 2507 F51 Plate |

| Super Duplex 2507 Alloy Sheet | SA 240 Type 2507 Strips |

| 25 Cr Super Duplex Steel Sheet | Saf 2507 Super Duplex Stainless Steel Strips |

| Super Duplex Stainless Steel 2507 Coil | Super Duplex Stainless Steel 25 Cr Sheet |

Difference Between Super Duplex Plate And Inconel Plate

Super Duplex

which request uncommon quality and corrosion resistance, Duplex 2507 may be a super duplex stainless steel planned for applications

Compositions (percentages) of Super Duplex

| Cr | Ni | Mo | C | N | Mn | Si | Cu | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 24.0-26.0 | 6.0-8.0 | 3.0-5.0 | 0.030 Max | .24-.32 | 1.20 Max | 0.80 Max | 0.50 Max | 0.035 Max | 0.020 Max | Balance |

Composition of Inconel

| Inconel | Element | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cr | Ni | S | Mo | Fe | Nb | Mn | Co | Cu | C | Ti | Al | Si | P | B | |

| 617 | 20.00 - 24.00 | 44.2 - 56.00 | 0.0015 | 8.00 - 10.00 | 3.00 | 0.5 | 10.00 - 15.00 | 0.5 | 0.15 | 0.6 | 0.8 - 1.5 | 0.5 | 0.0015 | 0.0006 | |

| 600 | 14.00 - 17.00 | 72.00 | 0.0015 | 6.00 - 10.00 | 1.00 | 0.5 | 0.15 | 0.5 | |||||||

| 690 | 30 | 59.5 | 0.0003 | 9.2 | 0.35 | 0.001 | 0.0019 | 0.002 | 0.35 | ||||||

| 601 | 20.00 - 23.00 | 58.00 | 0.0015 | 8.00 - 10.00 | 5.00 | 3.15 - 4.15 | 0.5 | 1.00 | 0.1 | 0.4 | 0.4 | 0.5 | 0.0015 | ||

| 718 | 17.00 - 21.00 | 50.00 - 55.00 | 0.0015 | 2.8 - 3.3 | balance | 4.75 - 5.5 | 0.35 | 1.00 | 0.2 - 0.8 | 0.008 | 0.3 | 0.65 - 1.15 | 0.35 | 0.0015 | 0.0006 |

| X-750 | 14.00 - 17.00 | 70.00 | 0.001 | 5.00 - 9.00 | 0.7 - 1.2 | 1.00 | 1.00 | 0.5 | 0.008 | 2.25 - 2.75 | 0.4 - 1.00 | 0.5 | |||

Super Duplex Ss Plate Stock

| MEASUREMENTS | KG/PLATE |

| 2 X 1500 X 3000 MM | 72 |

| 3 X 1500 X 3000 MM | 108 |

| 3 X 1500 X 6000 MM | 216 |

| 3 X 2000 X 6000 MM | 288 |

| 4 X 1500 X 3000 MM | 144 |

| 4 X 1500 X 6000 MM | 288 |

| 4 X 2000 X 6000 MM | 384 |

| 5 X 1500 X 3000 MM | 180 |

| 5 X 1500 X 6000 MM | 360 |

| 5 X 2000 X 6000 MM | 480 |

| 6 X 1500 X 3000 MM | 216 |

| 6 X 1500 X 6000 MM | 432 |

| 6 X 2000 X 6000 MM | 576 |

| 8 X 1500 X 3000 MM | 297 |

| 8 X 1500 X 6000 MM | 594 |

| 8 X 2000 X 6000 MM | 791 |

| 10 X 1500 X 3000 MM | 371 |

| 10 X 1500 X 6000 MM | 742 |

| 10 X 2000 X 6000 MM | 989 |

| 12 X 1500 X 3000 MM | 445 |

| MEASUREMENTS | KG/PLATE |

| 12 X 1500 X 6000 MM | 890 |

| 12 X 2000 X 6000 MM | 1187 |

| 15 X 1500 X 3000 MM | 557 |

| 15 X 1500 X 6000 MM | 1113 |

| 15 X 2000 X 6000 MM | 1484 |

| 20 X 1500 X 3000 MM | 742 |

| 20 X 1500 X 6000 MM | 1484 |

| 20 X 2000 X 6000 MM | 1978 |

| 25 X 1500 X 3000 MM | 927 |

| 25 X 1500 X 6000 MM | 1854 |

| 25 X 2000 X 6000 MM | 2472 |

| 30 X 1500 X 3000 MM | 1113 |

| 30 X 1500 X 6000 MM | 2225 |

| 30 X 2000 X 6000 MM | 2966 |

| 35 X 2000 X 4000 MM | 2240 |

| 40 X 1500 X 3000 MM | 1484 |

| 40 X 2000 X 6000 MM | 3956 |

| 45 X 2000 X 4000 MM | 2880 |

| 50 X 1500 X 3000 MM | 1854 |

| 50 X 2000 X 4000 MM | 3296 |

Welding Method Of Alloy 2507 Shim Sheet