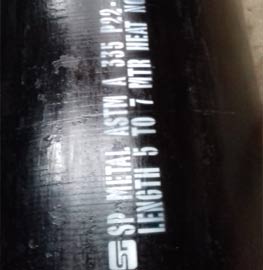

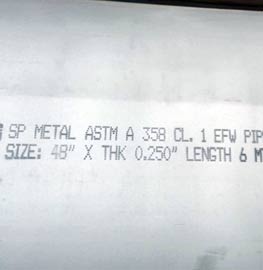

Seamless pipes are made of up different types of material including carbon, alloy, stainless Steel, etc. They are circular in shape, with a hollow section and no seams around it. These pipes are manufactured using the rot rolling, cold rolling, and the cold drawing procedures. They are often preferred over the welded ones as they are built using the monolithic steels billets. Due to the absence of a seam weld, they possess higher mechanical strength. One of the best things about these pipes is that they can effectively resist rust which increases their longevity. Sp Metal has become India's largest Exporter of Pipe and Tubes

- +91 22 66363099

- info@spmetal.net