- Size: 4 - 219mm

- Thickness: 0.5 - 20mm

- Length: Single, Double Random & Cut Length

- +91 22 66363099

- info@spmetal.net

What is Duplex Pipe used for?

A Duplex Pipe is composed of a microstructure of ferritic and austenitic grade of components this gives these pipes excellent strength and stability. These pipes are typically utilized in

Is 2205 Stainless Steel Tube expensive?

The price of stainless steel 2205 is expensive due to its unique manufacturing process, which is very complicated. The pipes in this grade are composed of two grains of stainless steel material namely austenitic and ferritic. The two-phase microstructure component offers higher strength and considerable corrosion resistance properties. These modules are stronger than normal grades of ferritic or austenitic components further, validating its higher costs.

UNS S31803 Pipe vs ASTM A790 UNS S32205 Material

A UNS S31803 Pipe and ASTM A790 UNS S32205 material have more similar characteristics than differences. The products from both these grades are used in some of the hardest and inhospitable production systems and applications. The major or the most noticeable difference between these grades is the higher nitrogen content in the S32205 grade. The nitrogen acts as an extra safety shield to the existent surface from corrosion and oxidation.

What are Alloy 2205 Pipes?

Alloy 2205 pipes are composed of an austenitic and ferritic grain microstructure with a 50-50 balance composition. These pipes are able to merge the qualities of both these structures and eliminate any weakness. Their unique composition gives these pipes superior mechanical strength and high resistance against pitting and cracking due to corrosion. These alloys have high strength if they are alloyed with nitrogen. Apart from this, the pipes in this grade have good abrasion, resistance to erosion, and good fatigue resistance. They possess a high-energy absorption rate with low thermal expansion.

2205 Duplex Steel Seamless Pipe Welding Process

Duplex steel pipes have excellent weldability and can be welded by most general procedures which are used in a standard austenitic grade of stainless steel. Most of the steel in this grade possess an alloyed filler which has 2% extra nickel concentration. These fillers ensure that the product doesn’t have to be heat treated after the fabrication process. Some of these processes include

Duplex Tube Corrosion

Duplex Tubes are high-grade austenitic modules that are highly resistant to stress corrosion cracking. They possess the same resistances as standard grades of stainless steel. These tubes can be used in a range of alkaline and acidic environments. Their high tolerance to intergranular corrosion gives them enhanced protection in chlorine sulfide systems.

Duplex Steel Tubing Characteristics

Some of the features of Duplex Steel Tubing include

Table of Content

Duplex Seamless Pipe Sizes

- Size: 4 - 219mm

- Thickness: 0.5 - 20mm

- Length: Single, Double Random & Cut Length

Sizes of Duplex UNS S31803 Welded Pipe

Duplex Pipe Specification

| Specification | ASTM A790 / ASME SA790 |

| Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

|---|---|

| Origin | European, Japanese, Korean, US, Russian, Indian (Strictly No Chinese Material) |

| Material Test Certificate (MTC) provided by duplex smls Pipe suppliers | ISO 14001:2015, PED, ISO 9001:2005, Ultrasonic Testing (UT), NDE, EIL, Radiographic Testing (RT), IBR, |

| Marking | All Pipes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

| Thickness | exact 0.25, 0.28, 0.32, 0.37, 0.41, 0.51, 0.61, 0.71, 0.91, 1.11, 1.15, 1.41 mm |

| size | 5.0 mm – 1219.2 mm |

| Supplier of Duplex 2205 Pipes offer various shapes | Round, Oval, Triangle, Semi-Round, Semi-oval, Rhomboid, Square, Rectangle, Hollow, Elliptical, Hollow, Semi-Rhomboid, |

| Outside Dia. | 6.00 Milimeter OD up to 914.4 Milimeter OD, Sizes up to 24 Inch NB available stock, Outside Dia Size Steel pipe available Ex-stock |

| Type | ERW / Seamless / Fabricated / Welded / CDW |

| Thickness Range | 0.3 milimerer – 50 milimerer, SCH10, SCH 5, SCH 80, SCH 40, SCH 160, SCH 80S,SCH XXS, SCH XS |

| Form | Square Pipes, Round Pipes, Rectangular Pipe |

| Length | Double Random ,Single Random & Required Length End: Beveled, Plain,Treaded |

| Dual certified supplier | Dual certified Duplex Tube suppliers in India, accordance to certify ASME SA790 and ASTM A790 American specifications |

| End Protection of pipes | Plastic Caps |

| Surface Finish: | 2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements |

| Delivery Condition | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Inspection, Test Reports | Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports |

| Packing | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials | Sizes and Specifications other than above can be manufactured on request |

| Our Presence | USA, Canada, Australia, UK, Malaysia, Poland, Iran, Italy, Singapore, UAE |

| Material Test Certificates (MTC) | Material Test Certificates (MTC) as per EN 10204/ 3.1B and EN 10204 3.2 |

| Seamless Pipe size | 5.0 mm – 1219.2 mm |

| Schedule | SCH5, SCH10, SCH40, STD, SCH80, SCH160 Supplier |

| Pipe End | Plain End, Beveled End, Treaded. |

| Size | 4 to 219mm W. T.: 0.5 to 20mm |

| Duplex Pipe Suppliers in India | |

Duplex Pipe

2205 Stainless Steel Tube

Equivalent of Duplex 2507 Tube

| GRADES | EN (WNR.) / UNS NO | TYPE |

|---|---|---|

| LDX 2101 Pipe | 1.4162/ S32101 | Lean |

| DX2202 | 1.4062/ S32202 | Lean |

| RDN 903 | 1.4482/ S32001 | Lean |

| LDX 2304 | 1.4362/ S32304 | Lean |

| 2205 Pipe | 1.4462/ S31803/ S32205 | Standard |

| 2507 Pipe | 1.4410/ S32750 | Super Duplex |

| Zeron 100 Pipe | 1.4501/ S32760 | Super Duplex |

| Ferrinox 255/ Uranus 2507Cu Pipe | 1.4507/ S32520/ S32550 | Super Duplex |

| Ferralium 255 Pipe | 1.4501/ UNS S32760 | Super Duplex |

| Hyper | 1.4658/ S32707 / S33207 | HDSS |

Duplex Stainless Tube Chemical Composition

| MATERIAL | COMPOSITION % (APPROX) | ||||||

|---|---|---|---|---|---|---|---|

| Cr | Ni | Mo | N | Mn | W | Cu | |

| 2101 LDX | 21.5 | 1.5 | 0.3 | 0.22 | 5 | - | - |

| DX2202 | 23 | 2.5 | 0.3 | 0.2 | 1.5 | - | - |

| RDN 903 | 20 | 1.8 | 0.2 | 0.11 | 4.2 | - | - |

| 2304 | 23 | 4.8 | 0.3 | 0.10 | - | - | - |

| 2205 | 22 | 5.7 | 3.1 | 0.17 | - | - | - |

| 2507 | 25 | 7 | 4 | 0.27 | - | - | - |

| Zeron 100 | 25 | 7 | 3.2 | 0.25 | - | 0.7 | 0.7 |

| Ferrinox 255/ Uranus 2507Cu | 25 | 6.5 | 3.5 | 0.25 | - | - | 1.5 |

2205 Stainless Steel Tube Mechanical Properties

| S31803 / S32205 | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi - 80000 , MPa - 550 | Psi - 116000 , MPa - 800 | 15 % |

Physical Properties of SAF 2205 Pipe

| Physical property | Value |

|---|---|

| Melting Range: | 2525-2630°F |

Specific Heat Capacity at 212°F | 0.119 Btu/lb/°F |

Thermal Conductivity at 212°F | 8.4 Btu/hr-ft-°F |

Poisson's Ratio | 0.3 |

Elastic Modulus at 72°F | 29 x 10 psi |

Duplex Pipe Price

| Description | Price in USD | Price in INR | Price in UAE Dirham |

|---|---|---|---|

| DUPLEX PIPES (TST-SAF2205-3-SCH10)(101.32 MTR) | $8.37 | 627 | 30.75 |

| STAINLESS STEEL PIPES 316 & DUPLEX STAINLESS STEEL PIPES 2205 | $2.10 | 157 | 7.70 |

| DUPLEX 2205 SMLS PIPE : 2 SCH 80S X 39.37L | $29.86 | 2,263 | 109.73 |

| STAINLESS STEEL DUPLEX SEAMLESS PIPES GRADE 2205 | $2.30 | 172 | 8.44 |

| STAINLESS STEEL DEFECTIVE WELDED PIPES GRADE 2205 | $1.48 | 111 | 5.44 |

Duplex Pipe Material Grade

Duplex Tubing Roughness

| Outside surface roughnes | Inside surface roughness |

| RA 20 defect level max. 50 μm | RA 20 defect level max. 20 μm |

Duplex SS Tubing Uses

Types of Duplex Stainless Steel Tubing

Get instant delivery Of 2 Inch Duplex 2205 Pipe, Weight Chart Of Duplex Stainless Steel Pipe, Duplex Pipe Suppliers in India.

Duplex Stainless Steel Pipe Test Certificate

Duplex 2205 Pipe Pressure Rating

| Pipe O.D. (In.) | Wall Thickness Of Pipe (Inches) | |||||||

|---|---|---|---|---|---|---|---|---|

| .028 | .035 | .049 | .065 | .083 | .095 | .109 | .120 | |

| Working Pressure (Psig) | ||||||||

| 1/8 | 7900 | 10100 | ||||||

| 1/4 | 3700 | 4800 | 7000 | 9500 | ||||

| 5/16 | 3700 | 5400 | 7300 | |||||

| 3/8 | 3100 | 4400 | 6100 | |||||

| 1/2 | 2300 | 3200 | 4400 | |||||

| 3/4 | 2200 | 3000 | 4000 | 4600 | ||||

| 1 | 2200 | 2900 | 3400 | 3900 | 4300 | |||

Characterisitcs of Duplex 2205 Pipe

Duplex Steel Tube Supplier

| Duplex 2205 Pipe | 4 inch ASTM A790 Duplex Steel Seamless Pipes |

| ASTM A790 Duplex Steel Pipes | Duplex Stainless Steel 2205 Welded Pipes |

| Duplex Steel 1.4462 Seamless Steel Pipe | S32205 Duplex Steel Cold Drawn Welded Pipes |

| ASTM A790 Duplex Steel Welded Pipes | Duplex Ss 2205 Cold Drawn Pipes |

| Duplex Stainless Steel 2205 ERW Pipes | Schedule 5S Duplex S32205 Seamless Pipes |

| Duplex Ss 2205 EFW Pipes | Schedule 40 Duplex Steel 2205 Pipes |

| Duplex S32205 Cold Drawn Seamless Pipes | Duplex Stainless Steel 2205 Precision Pipes |

| Duplex 2205 Seamless Steel Precision Pipes | High pressure Steel 1.4462 Pipes |

| Duplex Steel 2205 Cold Drawn Seamless Pipes | UNS S32205 Electropolished Pipes |

| Duplex Stainless Steel 2205 Custom Pipes | Duplex 2205 Cold Drawn Pipes |

| UNS S32205 Round Pipes | SS 2205 Exhaust Pipes |

| Duplex S32205 Square Pipes | S32205 Duplex Steel Thin Wall Pipes |

| UNS S32205 Rectangular Pipe | Small diameter Stainless Steel 2205 pipe |

| Steel 1.4462 Cold Drawn Pipe | Cold Drawn 2205 Welded Pipe |

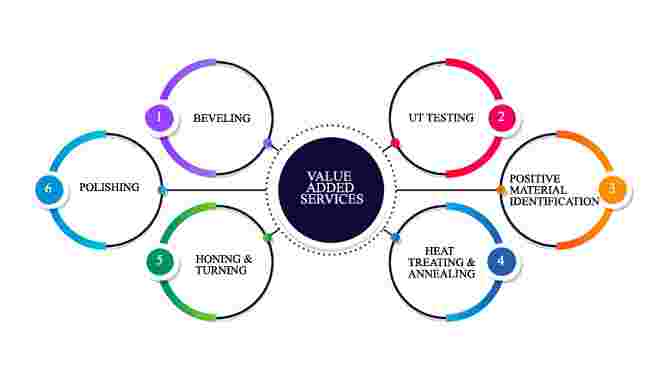

Value Added Services of Duplex 2507 Pipe

UNS S31803 Pipe Thickness

| Types | Out diameter | Wall thickness | Length |

|---|---|---|---|

| NB Sizes (in stock) | 1/8” ~ 8” | SCH 5 / SCH 10 / SCH 40 / SCH 80 / SCH 160 | Upto 6 Meters |

| Duplex 2205 Seamless Pipe (Custom Sizes) | 5.0mm ~ 203.2mm | As per requirement | Upto 6 Meters |

| Duplex 2205 Welded Pipe (in Stock + Custom Sizes) | 5.0mm ~ 1219.2mm | 1.0 ~ 15.0 mm | Upto 6 Meters |

Stock Range of Duplex 2205 Tube

| Pipe Form | Size Range | Thickness | Dimension Standards |

|---|---|---|---|

| 2205 Duplex Seamless Pipe, Duplex Steel 2205 Seamless Pipe | 1/8" to 16" inches | Sch 5, Sch 5s, Sch 10, Sch 10s, Sch 20, Sch 30, Sch 40s, Sch 40, Sch STD, Sch 60, Sch 80s, Sch 100, Sch 120, Sch XS, Sch XXS, Sch 160 | ANSI B36.10, ANSI B36.19, ANSI B36.19M |

Duplex Welded Pipe Advantage

Duplex Pipe Astm Code

ASTMA182 / ASME SA182 F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61.

Grade Comparison Chart of 2205 Duplex Stainless Steel Pipe

| China GB | ISO Unified Digital Code | ASTM / ASME | UNS code | EN Code | Company Commercial Grade |

| 022Cr23Ni4MoCuN | S23043 | S32304 | S32304 | 1.4362 | SAF2304 (Sandvik) |

| 022Cr22Ni5Mo3N | S22253 | S31803 | S31803 | 1.4462 | – |

| 022Cr23Ni5Mo3N | S22053 | S32205 | S32205 | 1.4462 | SAF2205 (Sandvik) |

| 022Cr25Ni7Mo4N | S25073 | S32750 | S32750 | 1.4410 | SAF2507(Sandvik) |

| 022Cr25Ni7Mo3WCuN | S22583 | S31260 | S31260 | – | – |

| 03Cr25Ni6Mo3Cu2N | S25554 | S32550 | S32550 | 1.4507 | UR52+ |

| 022Cr25Ni7Mo4WCuN | S27603 | S32760 | S32760 | 1.4501 | Zeron100 |

| 00Cr27Ni7Mo5N | – | S32707 | S32707 | – | SAF2707(Sandvik) |

Prestige quality Duplex Seamless Pipe Supplier in India offer in EN, DIN, ISO, BS, JIS or ANSI standard.

UNS S32205 Pipe Astm Standard

Heat Treatment of Astm A790 Uns S32205 Material

| UNS Designation | Temperature | Quenching |

| S31803 | 1870-2010 °F [1020-1100°C] | Rapid cooling in air or water |

| S32205 | 1870-2010 °F [1020-1100°C] | Rapid cooling in air or water |

| S31500 | 1800-1900 °F [980-1040°C] | Rapid cooling in air or water |

| S32550 | 1900 °F [1040°C] min. | Rapid cooling in air or water |

| S31200 | 1920-2010 °F [1050-1100°C] | Rapid cooling in water |

| S31260 | 1870-2010 °F [1020-1100°C] | Rapid cooling in water |

| S32001 | 1800-1950 °F [982-1066°C] | Rapid cooling in air or water |

| S32003 | 1850-2050 °F [1010-1120°C] | Rapid cooling in air or water |

| S32101 | 1870 °F min | Quenched in water or Rapidly cooling in other means |

| S32202 | 1870-1975 °F [1020-1080°C] | Rapid cooling in air or water |

| S32506 | 1870-2050 °F [1020-1120°C] | Rapid cooling in air or water |

| S32304 | 1700-1920 °F [925-1050°C] | Rapid cooling in air or water |

| S32750 | 1880-2060 °F [1025-1125°C] | Rapid cooling in air or water |

| S32760 | 2010-2085 °F [1100-1140°C] | Rapid cooling in air or water |

| S32950 | 1820-1880 °F [990-1025°C] | Rapid cooling in water |

| S32520 | 1975-2050 °F [1080-1120°C] | Rapid cooling in air or water |

SP Metals is an ISO certified Duplex 2205 Seamless Pipe Supplier in India & Duplex S31803 Seamless Pipe distributor in Mumbai

Duplex Pipe Hs Code

| HSN Code | Product Description |

|---|---|

| 7307 | Tube or pipe fittings (for example, couplings, elbows, sleeves), of iron or steel |

| 73072300 | Butt welding fittings |

| 7306 | Other tubes, pipes and hollow profiles (for example, open seam or welded, riveted or similarly closed), of iron or steel |

| 7306110 | Line pipe of a kind used for oil or gas pipelines: |

| 73061100 | Welded of stainless steel |

| 7304 | Tubes, pipes and hollow profiles, seamless, of iron (other than cast iron) or steel |

| 73042400 | Other of stainless steel |

Alloy 2205 Pipes Corrosion Resistance

Duplex stainless steel are extremely corrosion resistant. They have high resistance to intergranular corrosion. Even in chloride and sulphide environments, Duplex stainless steel exhibit very high resistance to stress corrosion cracking.

Duplex 2205 Seamless Pipe Heat Resistance

The high chromium content of Duplex stainless steel that p rotects against corrosion, causes embrittlement at temperatures over about 300°C.

At low temperatures duplex stainless steels have better ductility than the ferritic and martensitic grades. Duplex grades can readily be used down to at least -50°C.

Duplex S31803 Seamless Pipe Hardness

| Hardness, Max Brinell | Grade | Yield strength, min., ksi [MPa] | Tensile strength, min., ksi [MPa] | Elongation in 2 in., or 50mm, min, % |

| 290 | S32205 | 70 [485] | 95 [655] | 25 |

| 290 | S31803 | 65 [450] | 90 [620] | 25 |

| 297 | S32550 | 80 [550] | 110 [760] | 15 |

| 290 | S31500 | 64 [440] | 92 [630] | 30 |

| 290 | S31260 | 65 [450] | 100 [690] | 25 |

| 280 | S31200 | 65 [450] | 100 [690] | 25 |

| 310 | S32520 | 80 [550] | 112 [770] | 25 |

| 290 | S32304 | 65 [450] | 100 [690] | 25 |

| 290 | S32001 | 65 [450] | 90 [620] | 25 |

| 300 | S32760 | 80 [550] | 109 [750] | 25 |

| 310 | S32750 | 80 [550] | 116 [800] | 15 |

| 290 | S32950 | 70 [480] | 100 [690] | 20 |

Duplex Pipe Thermal Conductivity

| Temperature,°C | 20 | 400 | 200 | 100 | 300 |

|---|---|---|---|---|---|

| W/(m °C) | |||||

| Sandvik SAF 2205 | 14 | 20 | 17 | 16 | 19 |

| Temperature, °F | 68 | 800 | 400 | 200 | 600 |

|---|---|---|---|---|---|

| Btu/(ft h °F) | |||||

| Sandvik SAF 2205 | 8 | 12 | 10 | 9 | 11 |

Packaging of Seamless Duplex Stainless Steel Pipe

Elasticity Properties of Duplex Stainless Steel Tube

Units | 20°C | 200°C | 100°C | 300°C |

| Modulus of elasticity | 194 | 200 | 186 | 180 |

|---|---|---|---|---|

| psi x 10-6 |

Duplex 2205 Seamless Tube Features

Alloy 2205 Tubes Testing

ASTM A790 Uns S31803 Duplex Seamless Tube Surface Finish

| Cold drawn | CD | Polished | P |

| Bright drawn | BD | Slit rolled edge | SRE |

| Centreless ground | CG | Hot finished | HF |

| Cold finished | CF | Hot rolled annealed and pickled | HRAP |

| Peeled and turned | P And T | Rough turned/peeled | RT |

| Smooth turned | ST | Peeled and reeled | PR |

2205 Stainless Steel Tube Marking

ASTM A790 Duplex Heat Exchanger Tubes Density

| nits | 100°C | 20°C |

| Density | 7.8 | g/cm³ |

|---|---|---|

| 0.28 | lb/in³ |

Standards of Werkstoff Nr. 1.4462 Seamless Tubes