- +91 22 66363099

- info@spmetal.net

What is Titanium Pipes

Titanium Pipes offers double the strength of copper, steel and aluminum only with 50% of the material volume. This low density product provides temporal savings particularly to plumbing, flow tube and exhaust condition where frequently space is limited. These advantage exceed the raised prime cost of it which is a direct result of the processes required to withdraw it from ores such as Rutile and Ilmenite.

Its ultimate tolerance reduces the potential risk of dangerous line corrosion, valve breakages and leaks in industries where evaporative chemicals are processed. The flexibility of it also reduces the maintenance while expanding its durability.

Titanium Welded Pipe For Industrial Applications

Titanium ERW Pipe Welding

The most common welding methods for titanium and related alloys are gas tungsten-arc (GTA or TIG) and gas metal-arc (GMA or MIG). On titanium, resistance, plasma arc, electron beam, and friction welding are used to a lesser extent.

Titanium Pipes hardness and strength

Commercial-grade titanium has a tensile strength of roughly 63,000 psi. The softest grade of commercially pure titanium is at 240 MPa, although high-strength alloys can approach 1,400 MPa.

Temperature of Titanium Pipes

Titanium pipe alloys' maximum service temperature is limited by creep and oxidation resistance. Titanium pipe alloys nowadays are engineered to endure temperatures of up to 600 degrees Celsius.

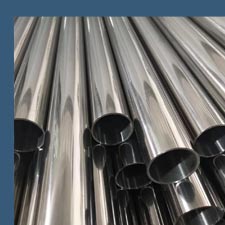

Titanium Pipe

Titanium Grade 2 Seamless Tubing

Titanium Tube

Gr.5 Square Tube

Types Of Titanium Grade 5 Pipe