- +91 22 66363099

- info@spmetal.net

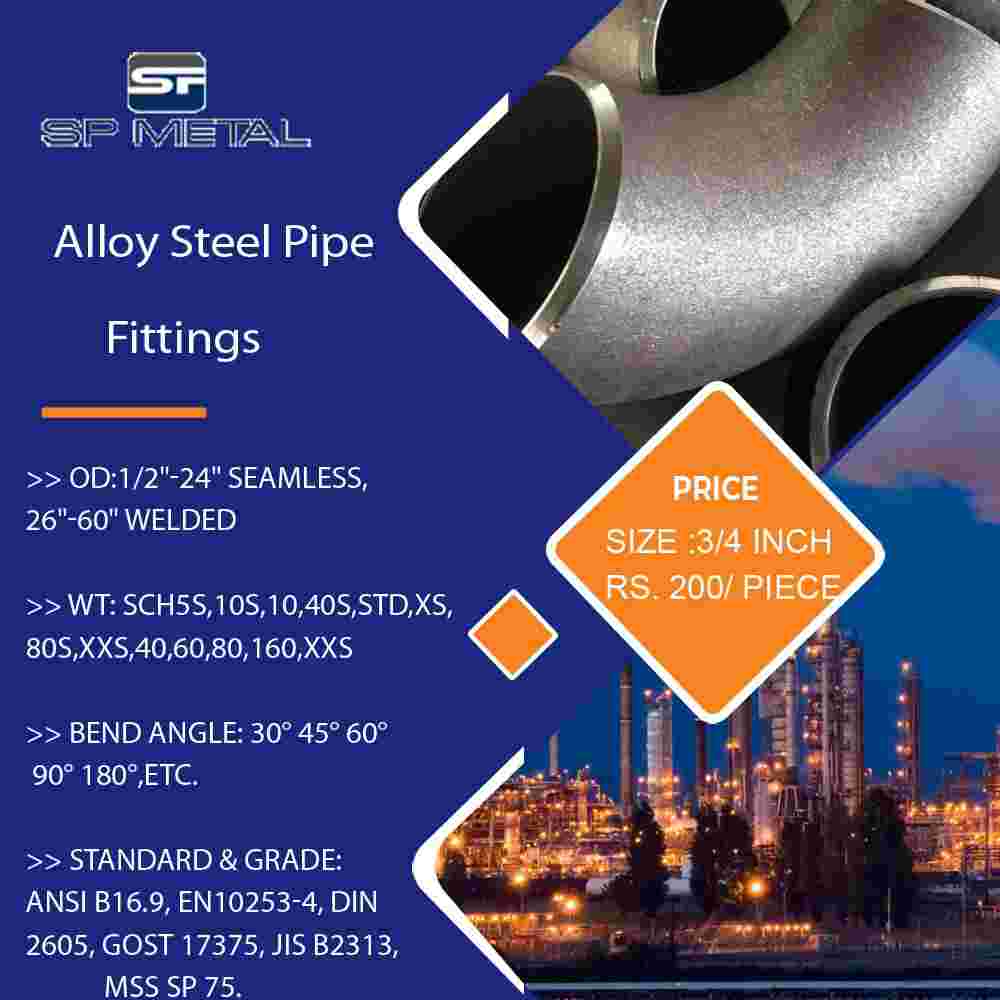

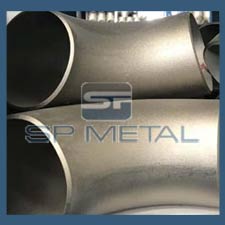

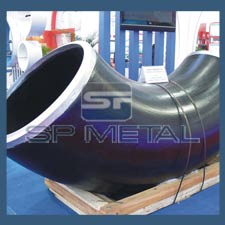

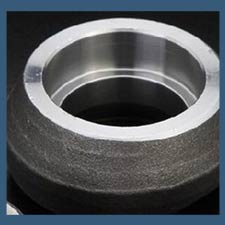

What is Alloy Steel Pipe Fittings?

Alloy steel pipe fittings are alloyed utilizing a range of alloys. The alloys exhibit superior performance and strength within these modules. Characterized as either low or high alloy steels, the fittings play an important part in influencing the features of the flow. The fittings have primary alloys of iron and copper that help them to effectively joining different types of piping modules.

ASTM A234 Wp11 Elbow vs Wp 22 Tee

Pipe fittings are unique components that influence the characteristics of gaseous and fluid flow across the system. Elbow and tees are the fittings of choice in this range, which can be classified based on certain features.

ASTM A234 Alloy Steel Buttweld Pipe Fittings Industrial Application

ASTM A234 Alloy Steel buttweld pipe fittings are strong and robust fittings that are employed across different industries. These high-strength fittings are a feature in pressures piping systems, vessel fabrication services of moderate to high temperatures. They are seen in use in chemical systems, nuclear piping, processing plants, plumbing, etc.

Comparision Between AISI 4130 Fittings and AISI 4140 Elbows

AISI 4130 fittings and AISI 4140 elbows are ultra-strength steel components that can be distinguished based on certain features:

ASTM A234 Wp12 90 Degree Elbow Characteristics

Characteristics of ASTM A234 Wp12 90 Degree elbow include:

Alloy Steel Buttweld Fittings Features

Some features of alloy steel buttweld fittings include:

Well-known Alloy Steel Pipe Fittings Manufacturer in India. For final AS Elbow 90 Price List Please Call on +91 22 6636 3099.

Table of Content

Alloy Steel Pipe Fittings Price List

| Description | Per Unit (INR) |

|---|---|

| PIPE FITTINGS ALLOY STEEL : DN 250, EQUAL TEE, SCH XS, SA182GR.WP9 | 397 |

| PIPE FITTINGS ALLOY STEEL : DN 150, 90 DEGREE ELBOW (LR), SCH 120, SA182 GR.WP9 | 533 |

| PIPE FITTINGS ALLOY STEEL : DN 100, END CAP, SCH 40/STD, SA182 GR.WP91 | 1,089 |

| PIPE FITTINGS ALLOY STEEL : DN400, 90 DEGREE ELBOW (LR), SCH60, SA182 GR.WP5 | 186 |

| PIPE FITTINGS ALLOY STEEL : DN400, 45 DEGREE ELBOW (LR), SCH60, SA182 GR.WP9 | 392 |

| PIPE FITTINGS ALLOY STEEL : DN 300, EQUAL TEE, SCH XS, SA182GR.WP9 | 383 |

| PIPE FITTINGS ALLOY STEEL : DN 100, EQUAL TEE, SCH XS/80, SA182 GR.WP11 | 216 |

| PIPE FITTINGS ALLOY STEEL : DN 400, EQUAL TEE, SCH 60, SA182GR.WP9 | 431 |

| PIPE FITTINGS ALLOY STEEL : DN 80, EQUAL TEE, SCH XS/80, SA182 GR.WP11 | 211 |

Looking for Alloy Steel Pipe Fittings suppliers who offer prompt delivery in Asia? Manufacturer of Alloy Steel Buttweld Fittings in India, call us for big discount and ready sizes, check latest price of Alloy Steel Elbow in Mumbai

Alloy Steel Fittings Specification

| Specification Chart | Alloy Steel Pipe Fittings |

|---|---|

| List Of Thickness | SCH 5/ SCH 10/ SCH 40/ SCH 50/ SCH 60/ SCH 80/ SCH 100/ SCH 120/ SCH 140/ SCH 160/ SCH 180 |

| Dimensions And Standard | ANSI B16.11ASME B16.28MSS-SP-43ASME/ANSI B16.9 |

| AS Fitting Chemical Composition | Mn (0.30-0.90), P (0.045), Si (0.10-0.50), C (0.28), S (0.045) Ect. |

| Vishal Steel Manufacturer Types Of Chrome Moly Pipe Fittings | Stub End/ Reducer/ End Cap/ Pipe Bend/ Elbow/ Tee |

| Type Of Connection | Threaded/ Flange/ End Bell/ Clamp End |

| Fitting Coating Faces | Anti-rust PaintCold and Hot Dip GalvanizedZinc PlatedYellow TransparentOil Black Paint |

| Machining Equipment Of AS Elbow 90: | Bending/ Pushing/ Press/ Electric Bevelling machine |

| Bending Radius | R=1D/ 2D/ 3D/ 5D/ 6D/ 8D/ 10D or Custom |

| Surface Treatment | Sand blasting/ Sand Rolling/ Sand Blasting |

| Application | Power/ gas/ petroleum/ chemical/ metallurgy/ shipbuilding etc. |

| Manufacturer Size | Buttweld ½" NB to 120" NBSeamless ½” to 24”Welded ½” to 120”Two Joint / Two Halve Fittings 6” to 48” |

| Our service | Nace Mr 01 75Sour ServiceImpact Test As Per Ug 84Macro Structure AnalysisHydrogen Induce Cracking Test (Hic)Sulphide Stress Cracking Test (Sscc)Cryogenic Services (Cryo),hydrogen Services (H2)Helieum Leak TestDye Peniterant Test (Dp)Magnetic Partius Test (Mp)Post Weld Heat Treatment (Pwht)Ultrasonic Test (Ut)Hydro Test, Etc. |

| Coating | Anti-rust Paint/ Zinc Plated/ Oil Black Paint/ Yellow Transparent/ Cold and Hot Dip Galvanized |

| Supporting Material | Gasket/ Ring Joint/ Flange Bolts |

| Test Certificates | EN 10204/3.1BRaw Materials Certificate100% Radiography Test ReportThird Party Inspection Report, etc |

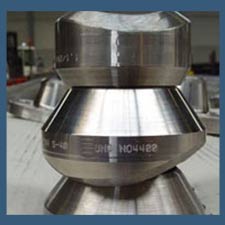

| Production Technique | Forged/ Heat treated and machined |

Alloy Steel Buttweld Fittings Weight Chart

| Products | Size |

| Annealed Alloy Steel Cups | 1/2'' NB to 14'' NB |

| Normalized Alloy Steel Stub Ends | 1/2'' NB to 14'' NB |

| Scm420 Chromoly Alloy Steel Socket Weld | Upto 2'' NB |

| 4142 Chromoly Alloy Steel Nipple | Upto 4'' |

| 4140 Low Alloy Steel Coupling | Upto 4''NB |

| Chromoly Alloy Steel Elbow | 1/2'' NB to 14'' NB |

| Cast Alloy Steel Reducer | 1'' NB to 14'' NB |

| Chromium Alloy Steel Tee | 1'' NB to 14'' NB |

Buy AS Fittings Directly From Largest Manufacturers In Mumbai, Check Dimensions Chart Of Chrome Moly Fittings

Manufacturer & Supplier Of Alloy Steel Tee, Alloy Steel Fittings In India

Alloy Steel Elbow Packaging

Alloy Steel Fittings Grade

ASTM A234 WP1 Buttweld Fittings

ASTM A234 WP5 Buttweld Fittings

ASTM A234 WP9 Buttweld Fittings

ASTM A234 WP11 Buttweld Fittings

ASTM A234 WP22 Buttweld Fittings

ASTM A234 WP91 Buttweld Fittings

PED Certified Chrome Moly Pipe Fittings Manufacturers in Mumbai, India, Dimensions Of IBR Alloy Steel Pipe Fittings In MM.

Corrosion Allowance Of Ibr Alloy Steel Pipe Fittings

(b) The thickness of tubes under external pressure shall be calculated as under:-

(b) The thickness of tubes under external pressure shall be calculated as under:-

| t = | WP' .D | + C | Equation XII/14 |

| 1.6f |

Check stock Of Chromoly Weld Fittings and Alloy Steel Weld Fittings Supplier & Manufacturers In Mumbai, India.

Alloy Steel Buttweld Fittings Types

Alloy Steel Tee Sizes

| Outside Daimeter (O.D.) & Inside Diameter (I.D.) | List Of Equivalent | (NPS) | Size Of Threads In Inch |

| 5/16 | 0.313 | 1/16 | 27 |

| 13/32 | 0.405 | 1/8 | 27 |

| 35/64 | 0.540 | 1/4 | 18 |

| 43/64 | 0.675 | 3/8 | 18 |

| 27/32 | 0.840 | 1/2 | 14 |

| 1-3/64 | 1.050 | 3/4 | 14 |

| 1-5/16 | 1.315 | 1 | 11-1/2 |

1-21/32 | 1.660 | 1-1/4 | 11-1/2 |

| 1-29/32 | 1.900 | 1-1/2 | 11-1/2 |

| 2-3/8 | 2.375 | 2 | 11-1/2 |

| 2-7/8 | 2.875 | 2-1/2 | 8 |

| 3-1/2 | 3.500 | 3 | 8 |

| 4 | 4.000 | 3-1/2 | 8 |

| 4-1/2 | 4.500 | 4 | 8 |

Alloy Steel Forged Fittings Types

Get instant delivery Of Low Alloy Steel Fittings , Schedule Chart Of Alloy Steel Forged Fittings, Alloy Steel Threaded Fittings Manufacturer In Mumbai. India.

ASTM A234 Wpb Elbow Chemical Composition

| WPB B,C,D,E, | WPC C,D,E, | WP11 CL1 | WP11 CL2, | WP11 CL3 | WP22 CL1 | WP22 CL3 | WP5 CL1, | WP5 CL3 | |

|---|---|---|---|---|---|---|---|---|---|

| Carbon | 0.3 | 0.35 | 0.05–0.15 | 0.05–0.20 | 0.05–0.20 | 0.05–0.15 | 0.05–0.15 | 0.15 | 0.15 |

| Manganese | 0.29–1.06 | 0.29–1.06 | 0.30–0.60 | 0.30–0.80 | 0.30–0.80 | 0.30–0.60 | 0.30–0.60 | 0.30–0.60 | 0.30–0.60 |

| Phosporus | 0.05 | 0.05 | 0.03 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 |

| Sulfur | 0.058 | 0.058 | 0.03 | 0.04 | 0.04 | 0.04 | 0.04 | 0.03 | 0.03 |

| Silicon | 0.10 min | 0.10 min | 0.50–1.00 | 0.50–1.00 | 0.50–1.00 | 0.5 | 0.5 | 0.5 | 0.5 |

| Chromium | 0.4 | 0.4 | 1.00–1.50 | 1.00–1.50 | 1.00–1.50 | 1.90–2.60 | 1.90–2.60 | 4.0–6.0 | 4.0–6.0 |

| Molybdenum | 0.15 max | 0.15 max | 0.44–0.65 | 0.44–0.65 | 0.44–0.65 | 0.87–1.13 | 0.87–1.13 | 0.44–0.65 | 0.44–0.65 |

| Nickel | 0.4 | 0.4 | |||||||

| Copper | 0.4 | 0.4 | |||||||

| Others | Vanadium 0.08 | Vanadium 0.08 |

Alloy Steel Fittings Mechanical Properties

| Gr. | Tensile Strength, min. ksi[MPa] | Yield Strength, min. ksi[MPa] | Elongation, min. % | |

| Longitudinal | Transverse | |||

| WP1 | 55-80[380-550] | 30[205] | 20 | 13 |

| WP12 CL1 | 60[415] | 32[220] | 22 | 14 |

| WP12 CL2 | 70[485] | 40[275] | 22 | 14 |

| WP11 CL1 | 60[415] | 30[205] | 22 | 14 |

| WP11 CL2 | 70[485] | 40[275] | 22 | 14 |

| WP11 CL3 | 75[520] | 45[310] | 22 | 14 |

| WP22 CL1 | 60[415] | 30[205] | 22 | 14 |

| WP22 CL3 | 75[520] | 45[310] | 22 | 14 |

| WP24 | 85[585] | 60[415] | 20 | - |

| WP5 CL1 | 60[415] | 30[205] | 22 | 14 |

| WP5 CL3 | 75[520] | 45[310] | 22 | 14 |

| WP9 CL1 | 60[415] | 30[205] | 22 | 14 |

| WP9 CL3 | 75[520] | 45[310] | 22 | 14 |

| WPR | 63-99[435-605] | 46[315] | 20 | - |

| WP91 | 90[620] | 60[415] | 20 | 13 |

| WP911 | 90-120[620-840] | 64[440] | 20 | 13 |

| WP92 | 90-120[620-840] | 64[440] | 20 | 13 |

Chromoly Weld Fittings Value Added Services

Alloy Steel Socket Weld Fittings Marking