- +91 22 66363099

- info@spmetal.net

What is Super Duplex Flanges?

Super Duplex Flanges are produced utilizing high alloy duplex steel. These flanges consist of a two-phase austenitic and ferritic microstructure. The superior concentration makes these flanges resistant to stress and corrosion cracking. The flanges within this grade securely seal a range of piping components and provide them with utmost stability. Apart from this, the superior mechanical properties within this grade allow these components to have excellent resistance to pitting due to chlorides, making them ideal for marine applications.

Difference Between ASME B16.47 Alloy 2507 Blind Flange and ASTM A182 gr F53 Slip On Flange

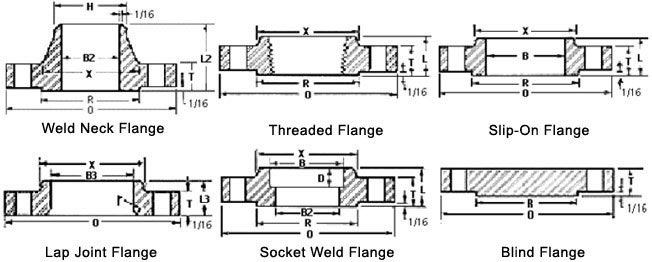

Flanges are piping equipment, which is classified based on the load-carrying capacity, temperature resistance, and face type. A blind and slip on flange are diverse flanges, which perform different functions in their respective systems.

Super Duplex 2507 Weld Neck Flange Application

Super Duplex 2507 Weld Neck Flange is characterized by a long protruding hub. The hub provides support and stability to piping components during vigorous movement and torsion. The grade is widely utilized in heat exchangers and chemical processing systems where temperatures and pressures keep on fluctuating. These flanges are also preferred in structural components and in the handling of volatile or hazardous fluids and gases.

ASTM A182 F55 UNS S32760 Reducing Flanges Vs ASTM A182 F54 UNS S32750 Socket Weld Flanges

ASTM A182 F55 UNS S32760 Reducing Flanges and ASTM A182 F54 UNS S32750 socket weld flanges are amongst the unique flanges in the piping industry. A reducing flange is employed in the system where there is a requirement of joining piping equipment of different sizes. These flanges are either welded, glued or bolted to the system. Socket weld flanges are preferred for smaller-sized pipes of different sizes. These pipes are inserted in a small recessed socket wherein they are welded using a fillet weld.

UNS S32550 F61 Super Duplex Threaded Flanges Features

Some of the features of the UNS S32550 F61 super duplex threaded flange includes:

Table of Content

Super Duplex Flanges

Alloy 2507 Blind Flange

ASTM A182 gr F53 Slip On Flange

Super Duplex Flange Specification

| ADNOC Approved Manufacturer Of Standards | API7S-43, API7S-15, API605, B16.47 Series B & A, ANSI/ASME B16.5, B16.48, BS Flanges, ASME Flanges, DIN Flanges, BS4504, DIN, BS 10, EN Flanges, EN-1092, ANSI Flanges, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, GOST Flange, ISO70051, BS1560-3.1, JISB2220, EN1092 |

|---|---|

| Size Chart | 1/2 Inch (15 NB) to 48 Inch (1200NB) DN10~DN5000 |

| JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| Pressure Rating ANSI | 900 LBS, 600 LBS, 2500 LBS, 300 LBS, 150 LBS,1500 LBS |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Pressure Calculation in DIN | 6Bar 16Bar 40Bar 25Bar 10Bar / PN16 PN10 PN6 PN64 PN25 PN40 |

| Coating | Zinc Plated, Anti-rust Paint, Cold and Hot Dip Galvanized, Oil Black Paint, Yellow Transparent |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Production technique |

|

| Specialized manufacturer of | Flat Face (FF), Ring Type Joint (RTJ), Raised Face (RF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Tongue, Large Tongue & Groove, Small Male-Female (SMF), Groove |

| Equipment | Pushing Machine, Bending machine, electric bevelling machine, Press machine, Sand-blasting machine etc |

| Origin | West Europe / Indian / USA / Japan / Korean |

| Test | Hydrostatic testing machine, X-ray detector, Direct-reading Spectrograph, UI trasonic flaw detector, Magnetic particle detector |

| Manufacturer of | Forged / Threaded / Screwed / Plate |

| Uses & application |

|

| Test Certificates | Manufacturer Test Certificate as EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Special design of SDSS Flanges | As per your drawing 15 NB (1/2") to 200 NB (8") |

| Material Test Certificates (MTC) as per EN 10204 3.2 and EN 10204 3.1, Test Certificates certifying NACE MR0175, NACE MR0103 | |

Buy duplex 2507 flanges Directly From Largest Manufacturers In Mumbai, Check Weight Chart Of ASME B16.47 super duplex 2507 flanges

Weight Chart Of Super Duplex 2507 Flanges

| Standard | Diameter | Class | Bolt Circle Diameter | Bolt Size | Number of Bolts | Diameter of Bolt Hole |

|---|---|---|---|---|---|---|

| ANSI B16.5 Flanges | 89 | ANSI 150 Flanges | 60 | 13 | 4 | 16 |

| 95 | ANSI 300 Flanges | 67 | 13 | 4 | 16 | |

| 95 | ANSI 600 Flanges | 67 | 13 | 4 | 16 | |

| 121 | ANSI 900 Flanges | 83 | 19 | 4 | 22 | |

| 121 | ANSI 1500 Flanges | 83 | 19 | 4 | 22 | |

| AS4087 Flanges | 95 | PN14 Flanges | 67 | M12 | 4 | 14 |

| AS 2129 Flange | 95 | Table C Flanges | 67 | 13 | 4 | 14 |

| 95 | Table D Flanges | 67 | 13 | 4 | 14 | |

| 95 | Table E Flanges | 67 | 13 | 4 | 14 | |

| 95 | Table F Flanges | 67 | 13 | 4 | 14 | |

| 114 | Table H Flanges | 83 | 16 | 4 | 17 | |

| 114 | Table J Flanges | 83 | 16 | 4 | 17 | |

| ISO 7005 (DIN) Flange | 80 | PN6 Flanges | 55 | M10 | 4 | 11 |

| 95 | PN10 Flanges | 65 | M12 | 4 | 14 | |

| 95 | PN16 Flanges | 65 | M12 | 4 | 14 | |

| 90 | PN20 Flanges | 60.5 | M14 | 4 | 16 | |

| 95 | PN25 Flanges | 65 | M12 | 4 | 14 | |

| 95 | PN40 Flanges | 65 | M12 | 4 | 14 |

Duplex 2507 Flanges Dimension

| AMERICAN SOCIETY OF MECHANICAL ENGINEERS (ASME) |

|

|---|

Well-known Manufacturer Of ASTM A182 F55 UNS S32760 Reducing Flanges in India. For final super duplex flange Price List Please Call on +91 22 6636 3099.

Super Duplex Stainless Steel Flanges Pressure Class

| ASME/ANSI B 16.47 | Blind Flange [Series A & B], Welding Neck Flange |

| PRESSURE CLASS | 300, 150, 900, 75, 600, 400 |

| ASME/ANSI B 16.5 | Slip on Flanges, Welding Neck Flanges, Blind Flanges, Socket Weld Flanges, High Hub Blind Flanges, Lap Joint Flanges, Ring Type Joint Flanges, Threaded Flanges |

| PRESSURE CLASS | 2500, 900, 400, 1500, 300, 150, 600 |

| ASME/ANSI B 16.36 | Threaded Flange Welding Neck Flanges, Slip on Flange, |

| PRESSURE CLASS | 600, 300, 400, 2500, 1500, 900 |

| BS 4504[PART 1] | Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange |

| BS 4504 SEC 3.1 | Hubbed Slip on Flange, Welding Neck Flange, Hubbed Threaded Flange, Plate Flange, Lapped Pipe End Flange, Loose Plate Flange, Blank Flange, Loose Plate With Weld Neck Flange |

| PRESSURE CLASS | PN 2.5 - PN 40 |

| PRESSURE CLASS | PN 2.5- PN 400 |

| BS10 | Welding Neck Flange, Screwed Boss Flange, Plate Slip-On Flange, Blind Flange Slip-On Boss Flange, |

| TABLE | F, H, D, E |

| DIN FLANGES | DIN 2636, 2641,2642, 2629, 2628, 2627, 2673 2576, 2637,2638, 2527, 2566, 2633, 2632, 2635, 2573, 2656, 2634, 2655, 2631 |

| BS 1560 BOSS | Socket Welding Flange, Welding Neck Flange, Blind Flange, Slip-On Flange, Lapped Flange, Screwed Boss Flange |

| PRESSURE CLASS | 300, 1500, 600, 400, 900, 2500, 150 |

| PRESSURE CLASS | PN 6 - PN 100 |

Chemical Behaviour Of ASTM A182 F55 UNS S32760 Reducing Flanges

| Grade | Mn | C | P | Si | S | N | Mo | Cr | Ni | Fe |

| S32760 | 1.00 max | 0.05 max | 0.030 max | 1.00 max | 0.010 max | 0.20 – 0.30 | 3.00 – 4.00 | 24.00 – 26.00 | 6.00 – 8.00 | 57.61 min |

| S32750 | 1.20 max | 0.030 max | 0.035 max | 0.80 max | 0.020 max | 0.24 – 0.32 | 3.00 – 5.00 | 24.00 – 26.00 | 6.00 – 8.00 | 58.095 min |

Equivalent Grades Of Alloy 2507 Blind Flange

| STANDARD | WERKSTOFF NR. | UNS |

| Super Duplex 2507 | 1.4410 | S32750 / S32760 |

Super Duplex 2507 Weld Neck Flange Mechanical Properties

| Grades | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| S32750 / S32760 | 7.8 | 0.281 | 1350 | 2460 |

ASTM A182 F61 Super Duplex Flange Price

| Description | Price in US | Price in India |

| super duplex forged flanges | US $2.50-$3.00 / Piece | 185.76 - 222.91 |

| super duplex 2507 stainless steel Socket-Weld flange | US $4.00-$4.50 / Piece | 297.21 - 334.37 |

| Asme b16.5 forged Super Duplex Stainless Steel 2507 RF WN Flange | US $13.00-$300.00 / Piece | 965.95 - 22291.08 |

| S32750 2507 hydraulic flange | US $100.00-$500.00 / Piece | 7430.36 - 37151.80 |

PED Certified 2507 Super Duplex Flanges Manufacturers in Mumbai, India, Dimensions Of ASTM A182 F61 Super Duplex Plate Flange In MM.

ASTM A182 Gr F53 Slip On Flange Fabricability

It should be hot worked in the range of 1250-1000 deg C, followed by a solution annealing at 1100 deg C and rapid quench.

Super Duplex Blind Flanges Dimension Chart

| Normal Pipe Size (NPS) | Outside Daimeter (O.D.) Of Flange | Thickness Of Flanges | Diameter of Raised Face | Hub at Base Diameter | Lengtd Tdru Hub | Bore And Diameter | Hub at Bevel Diameter | Radius of Fillet | Socket Deptd | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Weld Neck (WN) | SORF (Slip-On) NPT (Threaded) SWRF (Socket) | Loose (Lap Joint) | SORF (Slip-on) SWRF (Socket) | Loose (Lap Joint) | ||||||||

| O | Q | R | X | Y | Y | Y | W | B | H | r | Z | |

| 1/2 | 3-1/2 | 7/16 | 1-3/8 | 1-3/16 | 1-7/8 | 5/8 | 5/8 | .88 | .90 | .84 | 1/8 | 3/8 |

| 3/4 | 3-7/8 | 1/2 | 1-11/16 | 1-1/2 | 2-1/16 | 5/8 | 5/8 | 1.09 | 1.11 | 1.05 | 1/8 | 7/16 |

| 1 | 4-1/4 | 9/16 | 2 | 1-15/16 | 2-3/16 | 11/16 | 11/16 | 1.36 | 1.38 | 1.32 | 1/8 | 1/2 |

| 1-1/4 | 4-5/8 | 5/8 | 2-1/2 | 2-5/16 | 2-1/4 | 13/16 | 13/16 | 1.70 | 1.72 | 1.66 | 3/16 | 9/16 |

| 1-1/2 | 5 | 11/16 | 2-7/8 | 2-9/16 | 2-7/16 | 7/8 | 7/8 | 1.95 | 1.97 | 1.90 | 1/4 | 5/8 |

| 2 | 6 | 3/4 | 3-5/8 | 3-1/16 | 2-1/2 | 1 | 1 | 2.44 | 2.46 | 2.38 | 5/16 | 11/16 |

| 2-1/2 | 7 | 7/8 | 4-1/8 | 3-9/16 | 2-3/4 | 1-1/8 | 1-1/8 | 2.94 | 2.97 | 2.88 | 5/16 | 3/4 |

| 3 | 7-1/2 | 15/16 | 5 | 4-1/4 | 2-3/4 | 1-3/16 | 1-3/16 | 3.57 | 3.60 | 3.50 | 3/8 | 13/16 |

| 3-1/2 | 8-1/2 | 15/16 | 5-1/2 | 4-13/16 | 2-13/16 | 1-1/4 | 1-1/4 | 4.07 | 4.10 | 4.00 | 3/8 | 7/8 |

| 4 | 9 | 15/16 | 6-3/16 | 5-5/16 | 3 | 1-5/16 | 1-5/16 | 4.57 | 4.60 | 4.50 | 7/16 | 15/16 |

| 5 | 10 | 15/16 | 7.5/16 | 6-7/16 | 3-1/2 | 1-7/16 | 1-7/16 | 5.66 | 5.69 | 5.56 | 7/16 | 15/16 |

| 6 | 11 | 1 | 8-1/2 | 7-9/16 | 3-1/2 | 1-9/16 | 1-9/16 | 6.72 | 6.75 | 6.63 | 1/2 | 1-1/16 |

| 8 | 13-1/2 | 1-1/8 | 10-5/8 | 9-11/16 | 4 | 1-3/4 | 1-3/4 | 8.72 | 8.75 | 8.63 | 1/2 | 1-1/4 |

| 10 | 16 | 1-3/16 | 12-3/4 | 12 | 4 | 1-15/16 | 1-15/16 | 10.88 | 10.92 | 10.75 | 1/2 | 1-5/16 |

| 12 | 19 | 1-1/4 | 15 | 14-3/8 | 4-1/2 | 2-3/16 | 2-3/16 | 12.88 | 12.92 | 12.75 | 1/2 | 1-9/16 |

| 14 | 21 | 1-3/8 | 16-1/4 | 15-3/4 | 5 | 2-1/4 | 3-1/8 | 14.14 | 14.18 | 14.00 | 1/2 | 1-5/8 |

| 16 | 23-1/2 | 1-7/16 | 18-1/2 | 18 | 5 | 2-1/2 | 3-7/16 | 16.16 | 16.19 | 16.00 | 1/2 | 1-3/4 |

| 18 | 25 | 1-9/16 | 21 | 19-7/8 | 5-1/2 | 2-11/16 | 3-13/16 | 18.18 | 18.20 | 18.00 | 1/2 | 1-15/16 |

| 20 | 27-1/2 | 1-11/16 | 23 | 22 | 5-11/16 | 2-7/8 | 4-1/16 | 20.20 | 20.25 | 20.00 | 1/2 | 2-1/8 |

| 24 | 32 | 1-7/8 | 27-1/4 | 26-1/8 | 6 | 3-1/4 | 4-3/8 | 24.25 | 24.25 | 24.00 | 1/2 | 2-1/2 |

Various Types Of UNS S32760 Flanges

UNS S32750 Flanges Advantage

2507 Super Duplex Flat Flanges Packaging

UNS S32760 Rtj Flanges Bolt Size Chart

| 150# Flanges As Per ANSI B16.5 | 300# Flanges As Per ANSI B16.5 | 600# Flanges As Per ANSI B16.5 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Normal Pipe Size | # Studs And Bolts | Diameter of Studs And Bolts | Length Of Studs | # Studs And Bolts | Diameter of Studs And Bolts | Stud Length | # Studs And Bolts | Diameter of Studs And Bolts | Length Of Studs | |||

| 1/16 RF | RTJ | 1/16 RF | RTJ | 1/4 RF | RTJ | |||||||

| 1/2 | 4 | 0.50 | 2-1/4 | – | 4 | 0.50 | 2-1/2 | 3 | 4 | 0.50 | 3 | 3 |

| 3/4 | 4 | 0.50 | 2-1/2 | – | 4 | 0.63 | 3 | 3-1/2 | 4 | 0.63 | 3-1/2 | 3-1/2 |

| 1 | 4 | 0.50 | 2-1/2 | 3 | 4 | 0.63 | 3 | 3-1/2 | 4 | 0.63 | 3-1/2 | 3-1/2 |

| 1-1/4 | 4 | 0.50 | 2-3/4 | 3-1/4 | 4 | 0.63 | 3-1/4 | 3-3/4 | 4 | 0.63 | 3-3/4 | 3-3/4 |

| 1-1/2 | 4 | 0.50 | 2-3/4 | 3-1/4 | 4 | 0.75 | 3-1/2 | 4 | 4 | 0.75 | 4-1/4 | 4-1/4 |

| 2 | 4 | 0.63 | 3-1/4 | 3-3/4 | 8 | 0.63 | 3-1/2 | 4 | 8 | 0.63 | 4-1/4 | 4-1/4 |

| 2-1/2 | 4 | 0.63 | 3-1/2 | 4 | 8 | 0.75 | 4 | 4-1/2 | 8 | 0.75 | 4-3/4 | 4-3/4 |

| 3 | 4 | 0.63 | 3-1/2 | 4 | 8 | 0.75 | 4-1/4 | 4-3/4 | 8 | 0.75 | 5 | 5 |

| 3-1/2 | 8 | 0.63 | 3-1/2 | 4 | 8 | 0.75 | 4-1/4 | 5 | 8 | 0.88 | 5-1/2 | 5-1/2 |

| 4 | 8 | 0.63 | 3-1/2 | 4 | 8 | 0.75 | 4-1/2 | 5 | 8 | 0.88 | 5-3/4 | 5-3/4 |

| 5 | 8 | 0.75 | 3-3/4 | 4-1/4 | 8 | 0.75 | 4-3/4 | 5-1/4 | 8 | 1.00 | 6-1/2 | 6-1/2 |

| 6 | 8 | 0.75 | 4 | 4-1/2 | 12 | 0.75 | 4-3/4 | 5-1/2 | 12 | 1.00 | 6-3/4 | 6-3/4 |

| 8 | 8 | 0.75 | 4-1/4 | 4-3/4 | 12 | 0.88 | 5-1/2 | 6 | 12 | 1.13 | 7-1/2 | 7-3/4 |

| 10 | 12 | 0.88 | 4-1/2 | 5 | 16 | 1.00 | 6-1/4 | 6-3/4 | 16 | 1.25 | 8-1/2 | 8-1/2 |

| 12 | 12 | 0.88 | 4-3/4 | 5-1/4 | 16 | 1.13 | 6-3/4 | 7-1/4 | 20 | 1.25 | 8-3/4 | 8-3/4 |

| 14 | 12 | 1.00 | 5-1/4 | 5-3/4 | 20 | 1.13 | 7 | 7-1/2 | 20 | 1.38 | 9-1/4 | 9-1/4 |

| 16 | 16 | 1.00 | 5-1/4 | 5-3/4 | 20 | 1.25 | 7-1/2 | 8 | 20 | 1.50 | 10 | 10 |

| 18 | 16 | 1.13 | 5-3/4 | 6-1/4 | 24 | 1.25 | 7-3/4 | 8-1/4 | 20 | 1.63 | 10-3/4 | 10-3/4 |

| 20 | 20 | 1.13 | 6-1/4 | 6-3/4 | 24 | 1.25 | 8 | 8-3/4 | 24 | 1.63 | 11-1/4 | 11-1/2 |

| 24 | 20 | 1.25 | 6-3/4 | 7-1/4 | 24 | 1.50 | 9 | 10 | 24 | 1.88 | 13 | 13-1/4 |

Super Duplex Weld Neck Flanges Testing

S32750 Ring Spacer Flange Features

Suppliers Of Alloy 2507 Blind Flange In Mumbai, Super Duplex 2507 Weld Neck Flange Tolerance, ASTM A182 gr F53 Slip On Flange Stockist.

Dimensional Tolerance Chart Of Super Duplex Slip On Flanges

| 2507 Super Duplex Flanges | Tolerance Table | |

|---|---|---|

| A | O.D. (Outside Diameter) |

|

| D | Inside Diameter (I.D.) |

|

| B | Diameter of contact face |

|

| J | Diameter of hub at base |

|

| H | Diameter of hub at point of welding |

|

| P | Drilling |

|

| Eccentricity of bolt circle with respect to facing |

| |

| C | Thickness |

|

| K | Length of hub |

|

S32550 Lap Joint Flange Services

Check Size Chart Of super duplex stainless steel flanges And B16.5 sdss flange Supplier & Manufacturers In Mumbai, India.