- +91 22 66363099

- info@spmetal.net

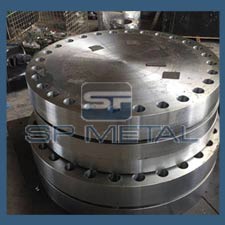

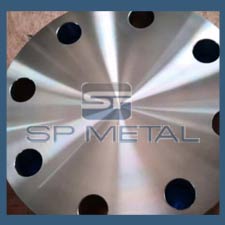

What is Stainless Steel Blind Flange?

A stainless steel blind flange is a flange designed without a face or a boring center. These flanges are utilized to curtail the hydraulic flow at the ends of tubings or other piping equipment. Blind flanges are versatile components, which can be availed with a flat or a raised face. A blind flange can be directly bolted on the piping equipment allowing room for cleaning and inspection. These flanges can withstand high pressures and corrosive media while managing to form a strong sealing within the system.

ASME B16.5 Blind Flange Uses

ASME B16.5 blind flanges have functions similar to a plug or a cap. These flanges help in terminating the flow of fluids, gases, air by sealing the ends of various piping systems. A blind flange can also act as a barrier to prevent the fluid movement to allow for modifications or repair in the system. Apart from this, they can also be utilized to check the pipe pressure for creating access points within the system.

ASTM A182 F304 Blind Flange vs ASTM A182 F316 Blind Flange

Stainless steel ASTM A182 F304 and ASTM A192 F316 blind flange blind flanges are amongst the grade of blind flanges which are widely utilized in the piping industry. Both these flanges are very identical visually, but there is some basic difference in their chemical composition, which differentiated both these components.

304 blind flanges have a chemical concentration of 18% chromium and 8% nickel. The 316 grade has a chemical concentration of 16% chromium, 10% nickel with 2% of molybdenum. The molybdenum concentration helps these flanges to fight against chloride pitting and makes them suitable for seawater applications. The superior chemical configuration makes the 316 blind flanges costlier than the 304-grade flange.

Differnce Between ANSI B 16.5 Class 600 Blind Flange and class 2500 Blind flange

ANSI B 16.5 Class 600 and class 2500 Blind flanges are differentiated based on their respective pressure classes. Pressure classes in flanges can be termed as the maximum allowable pressure a flange can withstand as the temperature gradually increases. A class 600 blind flange can withstand 890 psi of pressure at 600 degrees F. In the same case, class 2500 blind flange can tolerate 4730 psi of pressure at the same temperatures. The 600 flange is lighter, less robust, and smaller compared to the 2500 class blind flange.

SS 304 Blind Flange Grade

Other Materials Of Blind Flange

ASTM A182 SS Blind Flange Types