- +91 22 66363099

- info@spmetal.net

What is Stainless Steel 904L Pipe?

Stainless steel 904L Pipe is a non-stabilized super austenitic grade having a low carbon concentration. Pipes within this range are designed for moderate to high corrosion resistance services in a wide range of stress-induced environments. Having a good concentration of chromium and nickel content coupled with the additions of molybdenum and copper these pipes offer excellent resistance against corrosion cracking and crevice corrosion. The grade is non-magnetic and has excellent toughness, formability, and weldability. The high grade of contents utilized in producing these components makes these high-quality pipes expensive.

Difference Between ASTM B677 UNS N08904 Seamless Pipe and SS 904L ERW Tube

Piping equipment in the piping industry is generally produced utilizing some basic concepts. Seamless and Erw manufacturing process is one of the unique and oldest methods in producing these modules. Both these processing systems can be distinguished based on certain features.

ASTM A312 Tp 904L Material Length

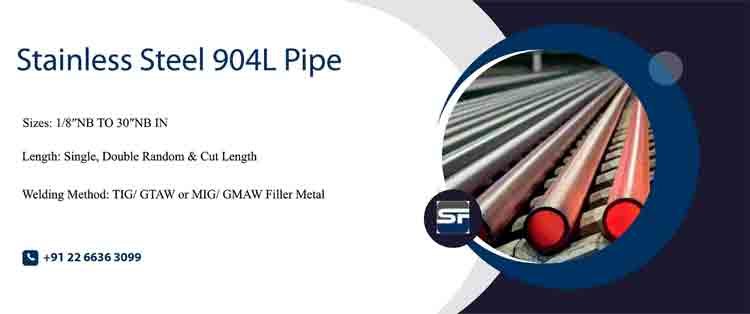

ASTM A312 Tp 904L is a very versatile metal, which is utilized in a range of applications. A 904L pipe is generally available with nominal sizes ranging between 1/4 to 30nm. These pipes are available in schedules between 5S to 80S. For seamless tubes, the sizes range between 3.35mm to 101.6mm and welded tubes between 6.35mm to 152mm.

AISI 904L Coiled Tubing vs Gr. 904L Boiler Tubes

Some major differentiating factors between AISI 904L Coiled tubing and Gr. 904L boiler tubes are listed below.

SS 904L Pipe Application

The major applications of the SS 904L Pipe include

Stainless Steel 904L Tubes Corrosion

All grades of stainless steel are prone to corrosion and rust. 904L grade tubes make use of high-grade raw materials, which make them highly resistant against corrosion compared to other grades. The addition of copper and molybdenum in the already exiting high concentration of chromium and nickel helps in improving the resistance of these tubes to reducing acids. The grade is also tolerant against general corrosion, stress corrosion cracking, along with crevice corrosion. Apart from this, has excellent tolerance against chloride attacks in seawaters.

Stainless Steel 904L Pipe

ASTM B677 UNS N08904 Seamless Pipe

SS 904L ERW Tube

ASTM A312 Tp 904L

ASME SA 213 Tp 904L

Types of ASTM B677 TP 904L Pipe