- +91 22 66363099

- info@spmetal.net

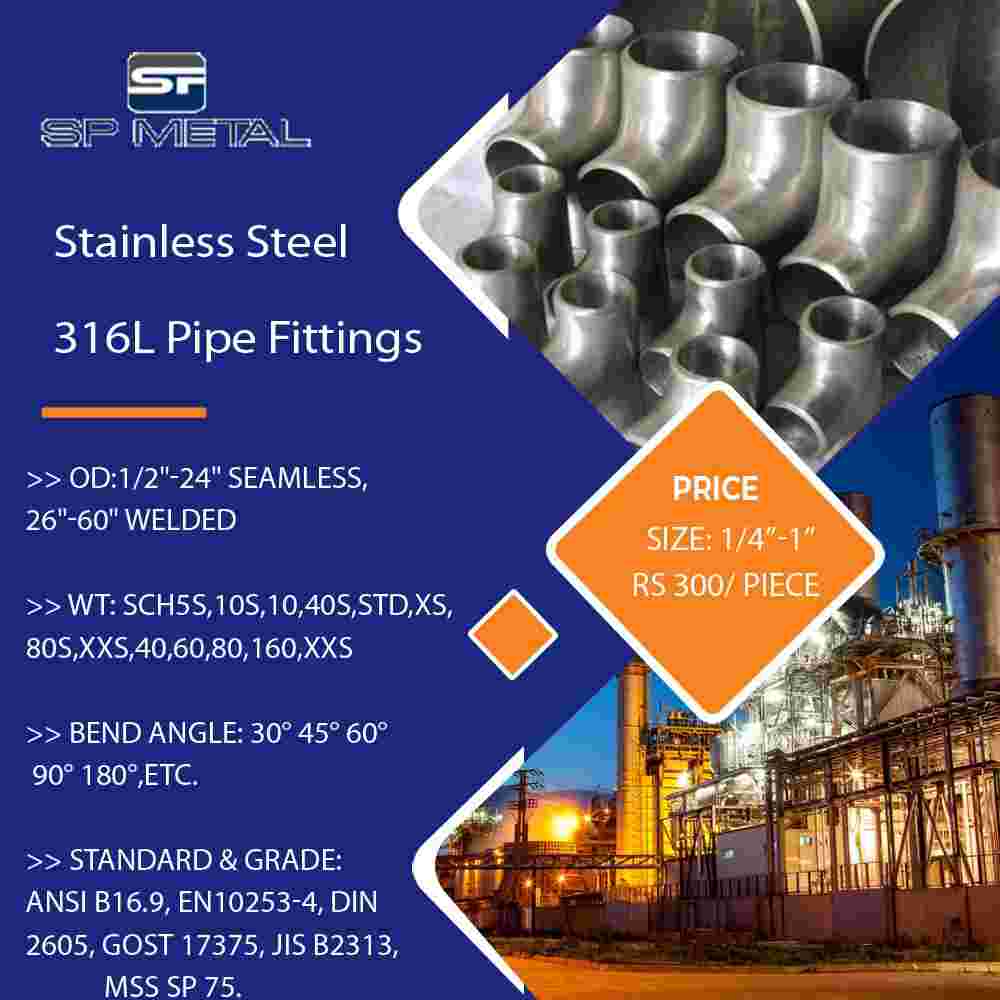

What is Stainless Steel 316L Pipe Fittings?

Stainless Steel 316L Pipe Fittings are a lower carbon concentration of the 316 grade. These pipe fittings possess a superior chemical concentration of chromium, nickel, and molybdenum. The superb concentration gives these modules enhanced corrosion and oxidation resistance. The fittings within this grade can withstand cryogenic to high temperatures. The lower carbon concentration within these fittings enables them to be welded easily. Apart from this, their superior tolerance to pitting by chlorides allows them to be used across different marine environments.

What is Stainless Steel 316L Fittings?

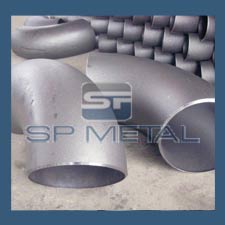

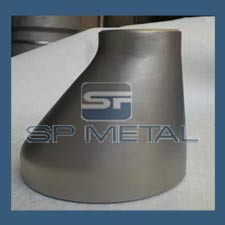

Stainless steel 316L Fittings are components, which effectively join a range of piping equipment within the system. The fittings within the 316L grade play a critical role in influencing the characteristics of the flow. Possessing excellent formability, the fittings can be employed to change the direction of flow or utilized in joining modules of uneven diameters. The fittings in this grade are available in the form of elbows, tees, crosses, caps, etc.

ASTM A403 WP 316L Tee Characteristics

Some characteristics of an ASTM A403 WP 316L Tee include:

SS 316L Pipe Fittings Uses

SS 316L pipe fittings showcase superior strength and performance. They are widely used in

Difference Between UNS S31603 Reducer and DIN 1.4404 Stainless Steel 316L Elbow

Elbows and reducers are common components utilized across this grade of stainless steel. Both these components play a critical role and influence different functions across the system.

Stainless Steel 316L Fittings

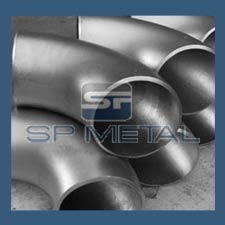

Stainless Steel 316L Elbow

ASTM A403 Wp 316L

Stainless Steel 316L Tee

Stainless Steel 316L Reducer

Stainless Steel 316L Pipe Fittings

Stainless Steel 316L Buttweld Fittings

Stainless Steel 316L Long Radius Elbow

Stainless Steel 316L Pipe Cap

316L Stainless Steel Fittings Types

Various Types of 316L Stainless Steel Socket Weld Fittings